The Revolutionary Impact of Carbon Fiber in Modern Aviation

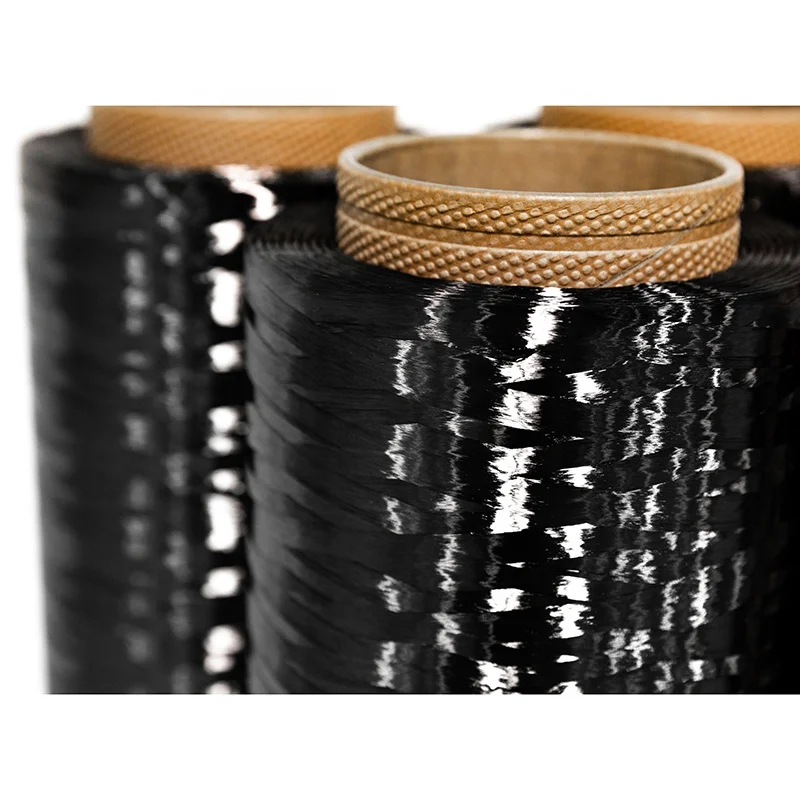

The aerospace industry has witnessed a transformative evolution with the integration of carbon fiber into aircraft manufacturing. This lightweight yet incredibly strong material has fundamentally changed how modern aircraft are designed and built. From commercial airliners to military jets, carbon fiber aircraft manufacturing has become the cornerstone of advancing aviation technology, offering unprecedented possibilities in terms of fuel efficiency, durability, and overall performance.

As manufacturers continue to push the boundaries of aerospace innovation, carbon fiber composites have emerged as the material of choice across numerous critical aircraft components. The strategic implementation of these advanced materials has led to lighter, more fuel-efficient aircraft while maintaining exceptional structural integrity and safety standards.

Primary Aircraft Structural Components

Fuselage Design and Construction

The aircraft fuselage represents one of the most significant applications of carbon fiber aircraft manufacturing. Modern commercial aircraft, such as the Boeing 787 Dreamliner, utilize carbon fiber composites for up to 50% of their primary structure, including the fuselage. This application allows for larger windows, improved cabin pressure, and better humidity control while reducing overall weight.

Carbon fiber's superior strength-to-weight ratio enables manufacturers to create larger, more spacious cabin designs without compromising structural integrity. The material's resistance to fatigue and corrosion also translates to reduced maintenance requirements and longer service life for aircraft fuselages.

Wing Structure Development

Aircraft wings are another critical area where carbon fiber technology has revolutionized manufacturing processes. The material's exceptional stiffness and ability to be molded into complex shapes make it ideal for creating aerodynamically efficient wing designs. Modern carbon fiber wings can be manufactured as single pieces, reducing the number of joints and potential failure points while improving overall structural efficiency.

The implementation of carbon fiber in wing construction has enabled manufacturers to develop longer, more flexible wings that enhance fuel efficiency and flight performance. These advanced wing designs can better handle the stresses of flight while maintaining optimal shape under varying load conditions.

Engine and Propulsion Systems

Engine Component Integration

Carbon fiber aircraft manufacturing plays a vital role in modern jet engine design, particularly in fan blades and engine casings. The material's high strength and low weight characteristics allow for larger fan diameters, improving engine efficiency without adding excessive weight. Additionally, carbon fiber engine components demonstrate superior resistance to heat and mechanical stress.

The integration of carbon fiber composites in engine nacelles and thrust reversers has resulted in significant weight reduction while maintaining structural integrity. These improvements directly contribute to reduced fuel consumption and enhanced engine performance across various flight conditions.

Propulsion System Efficiency

Beyond engine components, carbon fiber is extensively used in various propulsion system elements, including intake ducts and exhaust components. The material's ability to withstand high temperatures and maintain structural stability makes it ideal for these critical applications. Manufacturers have leveraged carbon fiber's properties to design more efficient propulsion systems that optimize thrust while minimizing weight.

The implementation of carbon fiber in propulsion systems has enabled the development of more advanced aerodynamic designs, contributing to improved fuel efficiency and reduced environmental impact. These innovations continue to drive the evolution of aircraft propulsion technology.

Interior and Secondary Structures

Cabin Interior Components

Carbon fiber aircraft manufacturing extends beyond primary structures to include various interior components. From overhead storage bins to seat structures, the material's versatility allows for lightweight, durable cabin furnishings that enhance passenger comfort while reducing overall aircraft weight. Modern cabin designs incorporate carbon fiber components to optimize space utilization and improve the flying experience.

The material's strength and design flexibility enable manufacturers to create innovative interior solutions that meet strict safety requirements while providing enhanced functionality. Carbon fiber's aesthetic properties also contribute to creating modern, sophisticated cabin environments that appeal to passengers.

Control Surface Applications

Aircraft control surfaces represent another critical application of carbon fiber technology. Ailerons, flaps, and rudders manufactured from carbon fiber composites offer superior performance characteristics while reducing weight compared to traditional materials. The precision manufacturing capabilities associated with carbon fiber allow for highly accurate control surface designs that enhance flight control and maneuverability.

The implementation of carbon fiber in control surfaces has improved aircraft responsiveness and handling characteristics across all flight regimes. These components demonstrate exceptional durability and resistance to environmental factors, contributing to reduced maintenance requirements and extended service life.

Future Developments and Innovations

Advanced Manufacturing Techniques

The future of carbon fiber aircraft manufacturing lies in developing more efficient production methods and advanced manufacturing techniques. Automated fiber placement systems and improved curing processes are revolutionizing how carbon fiber components are manufactured, reducing production time and costs while maintaining exceptional quality standards.

Emerging technologies in carbon fiber manufacturing, such as thermoplastic composites and hybrid materials, promise to further enhance the capabilities and applications of these materials in aircraft construction. These innovations will continue to drive improvements in aircraft performance and efficiency.

Sustainability and Environmental Impact

As environmental considerations become increasingly important, carbon fiber aircraft manufacturing is evolving to address sustainability challenges. Manufacturers are developing recycling techniques for carbon fiber composites and implementing more environmentally friendly production processes. These efforts align with industry goals to reduce aviation's environmental impact while maintaining the material's performance benefits.

The development of bio-based carbon fibers and sustainable manufacturing processes represents a promising direction for the future of aerospace materials. These innovations will help ensure that carbon fiber technology continues to advance while meeting growing environmental requirements.

Frequently Asked Questions

How does carbon fiber compare to traditional aircraft materials?

Carbon fiber offers significant advantages over traditional materials like aluminum, including higher strength-to-weight ratios, better fatigue resistance, and superior corrosion resistance. These properties enable the construction of lighter, more efficient aircraft while maintaining exceptional safety standards.

What are the maintenance requirements for carbon fiber aircraft components?

Carbon fiber components generally require less maintenance than traditional materials due to their resistance to corrosion and fatigue. However, specialized inspection techniques and repair procedures are necessary to ensure the ongoing integrity of carbon fiber structures.

How does carbon fiber contribute to fuel efficiency in aircraft?

The use of carbon fiber in aircraft manufacturing significantly reduces overall weight, which directly improves fuel efficiency. Additionally, carbon fiber's strength and design flexibility enable the creation of more aerodynamic structures that further enhance fuel economy during flight.