The manufacturing landscape has witnessed a remarkable transformation with the introduction of advanced composite materials, particularly forged carbon fiber, which has revolutionized how industries approach lightweight, high-strength applications. This innovative material combines the exceptional properties of traditional carbon fiber with unique manufacturing processes that create distinctive aesthetic patterns while maintaining superior mechanical characteristics. Industries ranging from aerospace to automotive have embraced forged carbon fiber solutions to meet increasingly demanding performance requirements while reducing overall weight and improving efficiency.

Understanding which sectors derive the greatest benefits from forged carbon fiber applications requires examining the specific demands and challenges each industry faces. The material's unique combination of strength-to-weight ratio, corrosion resistance, and design flexibility makes it particularly valuable in applications where traditional materials fall short. As manufacturing technologies continue to advance, more industries are discovering innovative ways to integrate forged carbon fiber solutions into their production processes, leading to improved product performance and competitive advantages.

Aerospace and Aviation Industry Applications

Commercial Aircraft Components

The aerospace industry stands as one of the primary beneficiaries of forged carbon fiber technology, where weight reduction directly translates to fuel efficiency and operational cost savings. Commercial aircraft manufacturers utilize forged carbon fiber in critical structural components, including wing assemblies, fuselage sections, and interior panels. The material's exceptional fatigue resistance ensures long-term reliability under the cyclic loading conditions experienced during flight operations, while its electromagnetic properties provide additional benefits for modern avionic systems.

Aircraft interior applications have seen significant adoption of forged carbon fiber solutions, particularly in cabin panels, overhead bins, and seat structures. The material's ability to maintain structural integrity while offering design flexibility allows manufacturers to create lighter aircraft interiors without compromising passenger safety or comfort. Additionally, the fire-resistant properties of properly treated forged carbon fiber meet stringent aviation safety standards, making it an ideal choice for critical cabin components.

Space Exploration and Satellite Technology

Space applications demand materials that can withstand extreme temperature variations, radiation exposure, and the vacuum of space while maintaining minimal weight. Forged carbon fiber excels in these harsh environments, providing the structural integrity required for satellite frames, solar panel supports, and spacecraft hulls. The material's low coefficient of thermal expansion ensures dimensional stability across the wide temperature ranges encountered in space missions.

Satellite manufacturers particularly benefit from forged carbon fiber applications in antenna systems and communication equipment housings. The material's electromagnetic transparency characteristics allow for optimal signal transmission while providing robust protection against space debris and micrometeorite impacts. These properties make forged carbon fiber an essential component in modern satellite design and space exploration technologies.

Automotive and Transportation Sector

High-Performance Vehicle Manufacturing

The automotive industry has embraced forged carbon fiber technology across multiple vehicle categories, from luxury sports cars to everyday passenger vehicles. High-performance manufacturers utilize forged carbon fiber in body panels, chassis components, and aerodynamic elements to achieve significant weight reductions while maintaining structural rigidity. The material's impact resistance and energy absorption capabilities make it particularly valuable in safety-critical applications such as crash structures and roll cages.

Racing applications have driven many innovations in forged carbon fiber manufacturing, where every gram of weight reduction can translate to improved lap times and competitive advantages. Formula racing teams extensively use forged carbon fiber in monocoque construction, wings, and suspension components. The material's ability to be molded into complex shapes while maintaining consistent mechanical properties allows engineers to optimize aerodynamic performance and structural efficiency simultaneously.

Electric Vehicle Integration

Electric vehicle manufacturers face unique challenges in balancing battery weight with vehicle range and performance. Forged carbon fiber solutions address these challenges by enabling significant weight reduction in structural components, effectively extending vehicle range without compromising safety or functionality. The material's electrical properties also provide benefits in battery housing applications, where electromagnetic shielding and thermal management are critical considerations.

Battery pack enclosures manufactured from forged carbon fiber offer superior protection against impacts while maintaining lighter weight compared to traditional metal alternatives. The material's corrosion resistance ensures long-term durability in various environmental conditions, while its design flexibility allows for optimized packaging of battery cells and cooling systems. These advantages make forged carbon fiber an increasingly important material in the rapidly growing electric vehicle market.

Marine and Offshore Industries

High-Performance Boat Construction

Marine applications benefit significantly from forged carbon fiber's resistance to saltwater corrosion and its ability to maintain structural integrity under dynamic loading conditions. Yacht builders and racing boat manufacturers utilize forged carbon fiber in hull construction, mast systems, and deck components to achieve optimal strength-to-weight ratios while reducing maintenance requirements. The material's fatigue resistance ensures long service life even under the harsh marine environment's constant stress cycles.

Racing sailboats particularly benefit from forged carbon fiber applications in rigging systems and sail handling equipment. The material's high tensile strength allows for smaller, lighter components that maintain safety margins while improving overall boat performance. Additionally, forged carbon fiber's ability to be shaped into complex geometries enables designers to create more efficient hull forms and appendages that enhance speed and maneuverability.

Offshore Energy Infrastructure

Offshore wind energy installations present unique challenges where forged carbon fiber solutions provide significant advantages. Wind turbine blade construction increasingly incorporates forged carbon fiber reinforcements to improve fatigue life and reduce maintenance costs. The material's corrosion resistance eliminates concerns about saltwater exposure, while its lightweight properties reduce tower loading and foundation requirements.

Oil and gas platforms utilize forged carbon fiber in specialized applications where weight reduction and corrosion resistance are paramount. Helicopter landing platforms, safety equipment, and instrumentation housings benefit from the material's durability and low maintenance requirements. The ability to manufacture complex shapes enables engineers to create integrated solutions that reduce installation time and improve operational efficiency.

Sports and Recreation Equipment

Professional Sports Equipment

Professional sports equipment manufacturers have revolutionized product performance through strategic implementation of forged carbon fiber technology. Tennis rackets, golf clubs, and bicycle frames constructed with forged carbon fiber offer superior performance characteristics compared to traditional materials. The material's ability to be tailored for specific stiffness and damping properties allows manufacturers to optimize equipment for different playing styles and performance requirements.

Cycling applications showcase forged carbon fiber's versatility in creating lightweight, aerodynamic frames that maintain exceptional stiffness for power transfer. Professional racing bicycles utilize forged carbon fiber in frame construction, wheels, and components to achieve weight targets while meeting safety standards. The material's vibration damping properties also improve rider comfort during long-distance events, providing competitive advantages in endurance racing applications.

Recreational Equipment Innovation

Consumer recreational equipment has seen widespread adoption of forged carbon fiber technology as manufacturing costs have decreased and production techniques have improved. Fishing rods, archery equipment, and sporting goods benefit from the material's combination of strength, sensitivity, and lightweight characteristics. The aesthetic appeal of forged carbon fiber's distinctive pattern has also made it popular in premium consumer products where appearance is as important as performance.

Water sports equipment, including surfboards, paddles, and kiteboarding gear, utilize forged carbon fiber to achieve optimal flex characteristics and impact resistance. The material's resistance to water absorption and UV degradation ensures long-term performance in harsh marine environments. These properties make forged carbon fiber an ideal choice for equipment that must maintain consistent performance across varying conditions and extended use periods.

Medical and Healthcare Applications

Surgical Instruments and Equipment

The medical industry has discovered unique applications for forged carbon fiber in surgical instruments and medical devices where biocompatibility, radiolucency, and sterilization compatibility are essential requirements. Surgical tables, imaging equipment components, and prosthetic devices benefit from forged carbon fiber's combination of strength and lightweight properties. The material's radiolucent characteristics allow for clear medical imaging without interference, making it valuable in diagnostic and surgical applications.

Orthopedic applications utilize forged carbon fiber in external fixation devices and surgical instruments where strength and corrosion resistance are critical. The material's biocompatible properties when properly processed make it suitable for temporary implant applications. Additionally, the ability to sterilize forged carbon fiber components using standard hospital procedures ensures compatibility with existing medical protocols and safety requirements.

Rehabilitation and Mobility Devices

Mobility assistance devices, including wheelchairs, crutches, and prosthetic components, benefit significantly from forged carbon fiber's lightweight and durable characteristics. These applications require materials that can withstand repeated loading cycles while maintaining structural integrity and user safety. Forged carbon fiber solutions enable the creation of lighter devices that reduce user fatigue while providing superior performance compared to traditional materials.

Advanced prosthetic limbs increasingly incorporate forged carbon fiber components to achieve more natural movement characteristics and improved user comfort. The material's ability to be engineered for specific stiffness and damping properties allows prosthetists to create devices that more closely mimic natural limb behavior. This customization capability represents a significant advancement in prosthetic technology and patient quality of life.

FAQ

What makes forged carbon fiber different from traditional carbon fiber materials?

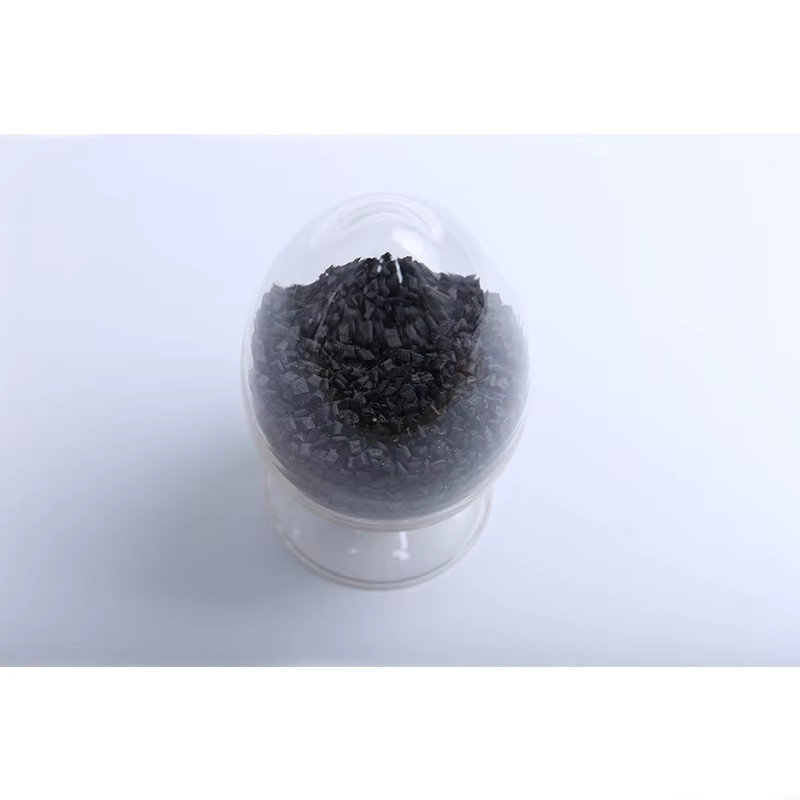

Forged carbon fiber differs from traditional carbon fiber through its unique manufacturing process that creates a distinctive woven appearance while maintaining superior mechanical properties. The forging process allows for more complex three-dimensional shapes and improved impact resistance compared to traditional layup methods. This manufacturing technique also enables better fiber distribution and reduces waste, making it more cost-effective for certain applications while providing enhanced aesthetic appeal.

Which industries see the fastest return on investment when implementing forged carbon fiber solutions?

The aerospace and high-performance automotive industries typically see the fastest return on investment from forged carbon fiber implementation due to the direct correlation between weight reduction and operational cost savings. In aerospace applications, reduced fuel consumption and increased payload capacity provide immediate economic benefits. Similarly, automotive manufacturers benefit from improved fuel efficiency and performance capabilities that translate to competitive market advantages and premium pricing opportunities.

Are there any limitations or challenges when working with forged carbon fiber in industrial applications?

Industrial implementation of forged carbon fiber faces challenges including higher initial material costs compared to traditional materials, specialized manufacturing equipment requirements, and the need for trained personnel familiar with composite processing techniques. Additionally, repair procedures can be more complex than traditional materials, requiring specialized knowledge and materials. However, these challenges are often offset by the long-term benefits of reduced maintenance, improved performance, and extended service life in demanding applications.

How does forged carbon fiber perform in extreme environmental conditions?

Forged carbon fiber demonstrates excellent performance across extreme environmental conditions, including wide temperature ranges, high humidity, UV exposure, and corrosive environments. The material maintains its mechanical properties from cryogenic temperatures to elevated operating temperatures, making it suitable for applications ranging from space exploration to desert operations. Its chemical inertness provides superior corrosion resistance compared to metals, while proper surface treatments can enhance UV resistance for long-term outdoor applications.

Table of Contents

- Aerospace and Aviation Industry Applications

- Automotive and Transportation Sector

- Marine and Offshore Industries

- Sports and Recreation Equipment

- Medical and Healthcare Applications

-

FAQ

- What makes forged carbon fiber different from traditional carbon fiber materials?

- Which industries see the fastest return on investment when implementing forged carbon fiber solutions?

- Are there any limitations or challenges when working with forged carbon fiber in industrial applications?

- How does forged carbon fiber perform in extreme environmental conditions?