What Is Carbon Fiber Prepreg and How Is It Made?

Composite materials have transformed industries that demand strength, lightness, and durability. Among these advanced composites, Carbon Fiber Prepreg has earned a reputation as one of the most important materials for high-performance applications. From aerospace and automotive to renewable energy, marine, and sports equipment, it plays a central role in modern engineering.

But what exactly is Carbon Fiber Prepreg, and how is it produced? Understanding its structure, composition, and manufacturing process is key to appreciating why it has become a cornerstone of advanced composites. This article provides a comprehensive overview of Carbon Fiber Prepreg, detailing what it is, how it is made, and why it matters.

Defining Carbon Fiber Prepreg

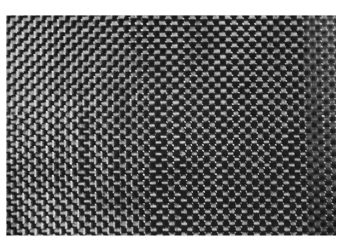

Carbon Fiber Prepreg refers to sheets or rolls of carbon fibers that have been pre-impregnated with a resin system, usually epoxy. Unlike dry fabrics, which require resin infusion during manufacturing, prepreg comes with the resin already applied in precise amounts. The resin is partially cured, a stage known as the B-stage, allowing the prepreg to remain flexible for handling but still requiring heat and pressure to achieve full curing.

This balance ensures that when the prepreg is finally processed in an autoclave or oven, the resin fully crosslinks, binding the carbon fibers into a strong, durable composite part. By controlling the fiber-to-resin ratio in the factory, manufacturers can guarantee consistent quality and performance across every sheet.

Why Carbon Fiber Prepreg Is Important

Carbon Fiber Prepreg has advantages that make it indispensable in industries requiring advanced materials. It offers an excellent strength-to-weight ratio, fatigue resistance, thermal stability, and design flexibility. These qualities make it vital in applications where performance and safety cannot be compromised.

For example, aircraft components made from Carbon Fiber Prepreg are lighter yet stronger than aluminum, reducing fuel consumption and increasing payload capacity. Race cars benefit from improved speed and handling with lighter body panels and chassis structures. Wind turbines use prepreg-based blades that capture more energy while withstanding extreme weather conditions.

The Basic Components of Carbon Fiber Prepreg

To understand how Carbon Fiber Prepreg is made, it is important to know the two main components:

Carbon Fibers

Carbon fibers are extremely fine filaments composed mostly of carbon atoms aligned in a crystalline structure. They provide the tensile strength and stiffness of the prepreg. Carbon fibers are typically produced from precursors like polyacrylonitrile (PAN) or pitch, which are processed under high heat to form strong, lightweight fibers.

Resin System

The resin matrix binds the fibers together and transfers loads between them. Epoxy is the most common resin system used, but bismaleimide (BMI), phenolic, or polyimide resins may also be employed for higher temperature resistance. The resin system is designed to partially cure during the prepregging process, leaving it tacky and flexible for handling.

The Manufacturing Process of Carbon Fiber Prepreg

The production of Carbon Fiber Prepreg is a highly controlled process. Every step is designed to ensure uniform fiber impregnation, consistent resin content, and material quality.

Step 1: Preparing the Carbon Fiber Reinforcement

Carbon fibers are provided in different forms, such as unidirectional tape, woven fabric, or multiaxial fabrics. The choice depends on the intended application. Unidirectional tapes provide maximum strength in one direction, while woven fabrics offer multidirectional reinforcement.

Step 2: Applying the Resin System

The fibers are passed through a resin application system, where the resin is applied evenly across the fabric. There are several methods used:

Hot-Melt Process: The most common technique, where the resin is melted and spread onto carrier paper before the carbon fibers are pressed into it. Heat and pressure ensure uniform impregnation.

Solvent-Dip Process: The fabric is dipped into a resin solution. After impregnation, the solvent is evaporated, leaving the resin distributed through the fibers.

Film Process: Thin resin films are layered with carbon fabrics, and heat and pressure consolidate them into a single prepreg sheet.

The hot-melt method is the most widely used because it offers better control over resin content and reduces environmental concerns associated with solvents.

Step 3: Partial Curing to B-Stage

Once impregnated, the resin is partially cured to the B-stage. This ensures that the prepreg is tacky enough to adhere to molds during layup but not fully hardened. The B-stage state is what allows the material to be stored, shipped, and handled before its final curing stage.

Step 4: Packaging and Storage

After preparation, the Carbon Fiber Prepreg is cut into sheets or rolled onto spools and packaged under airtight, protective films to prevent contamination and moisture absorption. Since the resin remains reactive at room temperature, prepregs are stored in freezers at around -18°C to preserve shelf life.

Storage and Handling Considerations

Carbon Fiber Prepreg must be carefully managed to maintain its performance. If stored at room temperature, it begins to cure prematurely, reducing its working life. Manufacturers track out-time, which refers to the total time prepreg can remain at ambient conditions before becoming unsuitable for use.

When removed from cold storage, prepreg must be thawed gradually in sealed packaging to prevent condensation. Handling requires gloves and clean environments to avoid contamination from oils, dust, or moisture.

Curing: The Final Step in Processing

Once laid into molds, Carbon Fiber Prepreg requires curing to become a solid composite structure. This step typically occurs in an autoclave, where heat and pressure are applied simultaneously to achieve full resin crosslinking and consolidate the fibers.

Curing temperatures for epoxy prepregs usually range from 120°C to 180°C, while advanced resin systems may require over 200°C. The application of pressure ensures that air voids are eliminated and the laminate achieves maximum density and mechanical strength.

Advantages of Prepreg Over Other Composite Methods

The production of Carbon Fiber Prepreg ensures several advantages over other composite manufacturing methods such as wet layup or resin transfer molding:

Consistent resin-to-fiber ratio for reliable mechanical properties.

Reduced risk of voids and defects.

Better surface finish and dimensional accuracy.

Simplified layup with tacky prepreg layers that adhere easily to molds.

These qualities explain why Carbon Fiber Prepreg is favored for critical applications where failure is not an option.

Applications That Depend on Carbon Fiber Prepreg

Carbon Fiber Prepreg is found across a wide range of industries:

Aerospace: Aircraft fuselages, wings, tail sections, and spacecraft components.

Automotive: Race car chassis, high-performance body panels, and lightweight interior components.

Renewable Energy: Wind turbine blades designed for durability and efficiency.

Marine: High-performance yachts and racing boats.

Sports Equipment: Bicycles, tennis rackets, golf clubs, and skis.

Electronics: Drones, laptops, and premium consumer devices.

In each application, the material delivers a balance of lightness, strength, and durability that cannot be matched by metals or traditional composites.

Challenges in Working With Prepreg

Despite its many advantages, Carbon Fiber Prepreg is not without challenges. These include:

High Cost: The production process and storage requirements make it more expensive than other composites.

Storage Sensitivity: Requires freezing and careful tracking of out-time.

Processing Complexity: Often requires autoclaves, which add to capital costs.

Limited Shelf Life: Even under optimal conditions, prepreg must be used within a certain timeframe.

These challenges explain why prepreg is often reserved for high-end industries where performance justifies the cost.

Future Innovations in Carbon Fiber Prepreg

Research and development are pushing the boundaries of what Carbon Fiber Prepreg can do. Future innovations may include:

Out-of-autoclave prepregs that cure without the need for expensive equipment.

Toughened resin systems that increase temperature resistance and durability.

Recyclable prepregs designed to meet sustainability goals.

Automated layup systems that improve efficiency and reduce labor costs.

These advancements will make prepregs more accessible to broader industries, expanding their use beyond aerospace and automotive into construction and mainstream consumer products.

Conclusion

Carbon Fiber Prepreg is a sophisticated composite material that combines carbon fiber strength with resin system versatility. Produced through controlled processes that ensure precision resin impregnation and consistent quality, it provides unmatched performance in industries where lightweight strength is essential.

From aerospace to sports equipment, Carbon Fiber Prepreg enables innovation by offering superior strength-to-weight ratios, fatigue resistance, dimensional stability, and design flexibility. While cost, storage requirements, and processing challenges remain, the benefits far outweigh the drawbacks for high-performance applications.

As manufacturing technologies advance and new resin systems are developed, Carbon Fiber Prepreg will continue to dominate the composite materials landscape, setting the standard for strength, precision, and reliability.

FAQ

What makes Carbon Fiber Prepreg different from dry carbon fabrics?

Carbon Fiber Prepreg already has resin applied in controlled amounts, while dry fabrics require resin infusion during processing.

How is Carbon Fiber Prepreg stored?

It is stored in freezers at around -18°C to prevent premature curing and extend shelf life.

What industries use Carbon Fiber Prepreg the most?

Aerospace, automotive, renewable energy, marine, and sporting goods are the leading industries.

Can Carbon Fiber Prepreg be processed without an autoclave?

Yes. Out-of-autoclave technologies are emerging, though autoclaves remain the gold standard for high-quality curing.

Why is Carbon Fiber Prepreg so expensive?

Its cost reflects precision manufacturing, storage requirements, and curing processes that ensure exceptional performance.

Table of Contents

- What Is Carbon Fiber Prepreg and How Is It Made?

- Defining Carbon Fiber Prepreg

- Why Carbon Fiber Prepreg Is Important

- The Basic Components of Carbon Fiber Prepreg

- The Manufacturing Process of Carbon Fiber Prepreg

- Storage and Handling Considerations

- Curing: The Final Step in Processing

- Advantages of Prepreg Over Other Composite Methods

- Applications That Depend on Carbon Fiber Prepreg

- Challenges in Working With Prepreg

- Future Innovations in Carbon Fiber Prepreg

- Conclusion

- FAQ