Түсіну Препрег материалдары Негізгі қағидалар

Препрег материалдары неліктен өзара табысты?

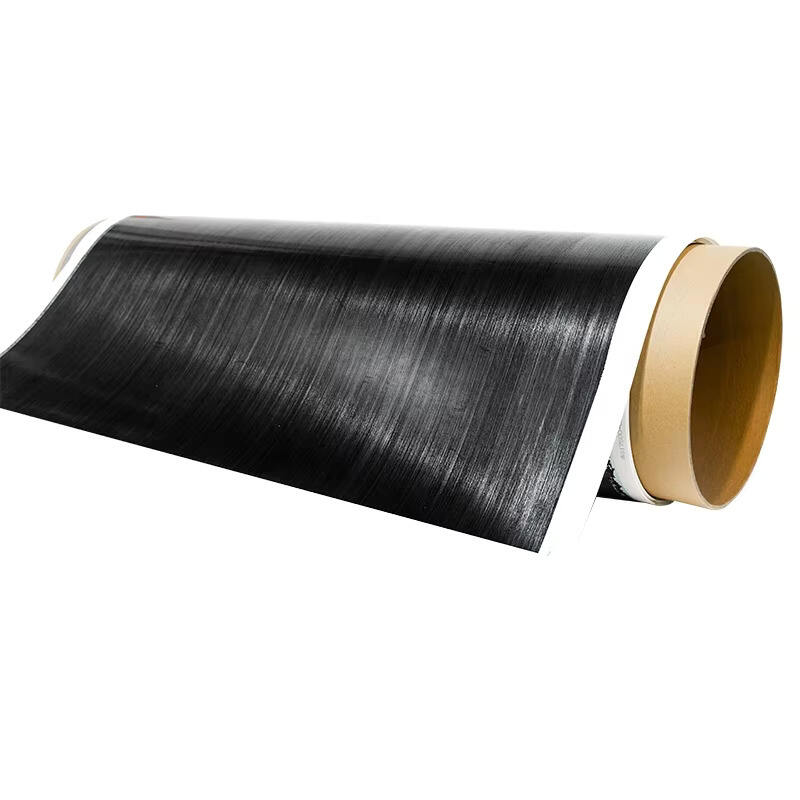

Препрегтер арматуралы талшықтар мен шайыр негізін біріктіріп, шайырдың салмағы мен ылғалдылығын бақылау үшін алдын ала сіңдірілген. Бұл құрам маңызды, өйткені ол тұрақтылықты қамтамасыз етеді және жоғары өнімділікпен жұмыс істейтін материалдар үшін қолайлы жоғары сапалы материалдарды өндіру үшін өте маңызды.

Жалпы композиттік материалдардан айырмашылығы, препрегдер жоғары температурада (40-50 °C) қатайтуды ұстанады. Салмағы мен беріктігі арақатынасының төмендеуі - бұл препрегтердің артықшылықтарының бірі ғана, олар әуе және автомобиль өнеркәсібі сияқты өнеркәсіптерде ерекше маңызды, онда салмақты азайту, беріктікті бұзбай, өте маңызды. Төмен материал үшін жоғары беріктікті қамтамасыз ету қабілеті арқасында алдын ала ойлаушы инженерлік шешімдерде көбірек қарастырылуда.

Негізгі компоненттер: Резиналар және волокно толықтырулар

Прегрег материалдың әсерлілігі үлкен жәрдемді резиналар мен волокно толықтырулардың таңдауына байланысты. Эпоксид, фенолдық немесе BMI сияқты резиналар ақырындағы композиттің қызмет көрсету қасиеттерін бас тартады, термік стабильдік пен механикалық силик сияқты факторларға әсер етеді.

Бірақ, үшбұрыштық және стекрөлдер сияқты рөлдердің күштілік пен тегістікті қамтамасыз ету үшін маңызды. Осы өзара әсерлердің зерттеуі - қажетті механикалық қабілеттерді дамытуға негізделген. Мисалы, шыны мен рөлдердің комбинациясының таңдауы - әдетпен қоңырау атауынан тыс жылдарға дейінгі автокөлік бөліктері мен өзекті термік және механикалық қасиеттерге ие ушин-ушар аероспейс компоненттері үшін критикалды.

Саламыстың қажеттіліктерін басқару қажет

Аероспейс және автомобильдік салалар – әдетте оның қабілеттеріне сәйкес болатын таңбаланған prepreg шешімдерін қажет ететін салалар. Аероспейс саласында, қуыршақты, бірақ ұзақ өмір сүретін материалдарды пайдалану – строгталық қауіпсізлік стандарттарын қанағаттандыру үшін маңызды, бұл да high-performance prepregs үшін талапты жоюға ықпал етеді.

Сондай-ақ, автокөлік секторы қуаттылықты кеміту және қызмет етуді жеткізу мақсатында қысқартылған prepregs-терді кеңінен қолданады. Транспорттан басқа, ветер энергиясы секторы қысқартылған Prepregs-тердің формуласымен ұзақ өмір сыйлықтары болатын 'қиын' орталықтарда пайдалануға болады. Медициналық аппараттардың құруы да осы құтқармаш материалдарды регулацияларға сәйкес қызмет ету қажеттілігі мен қызмет етудің спецификациясына сәйкес келу үшін қолданады. Бұл тапсырмалар Prepregs-терді әртүрлі секторларға қолдану үшін жасау қажеттілігін көрсетеді.

Қадам-қадамды қуыршақтарды бастапқы құру процесі

Сіздің қызметтік талаптарыңызды таңдау

Белгілі талаптарға сай қуыршақ материалдарды бастапқы құру процессінде осы қадам негізгі. Қуыршақты қолдану үшін қолданыстағы шарттарды қарастыру маңызды, мисалы, жоғары жүкке қарсы қабілет, температуралық қарым-қатынасты қарастыру және қорғаныштық факторлар.

Инженерлер меншік білімділерімен жақын қосымша көрсету мүмкіндігін беретін тәжірибелік көрсеткіштерді анықтауда құнды рахаттық береді. Бұл талаптарды белгілей отырып, біз дәлелді пікірді пайдаланып, дұрыс подготовка материалдарын және өңдеу әдістерін таңдауға болады, сонымен қатар ең жақсы жұмыс істейтін және сенімділік қамтиды.

Резин-меншік комбинациясын таңдау

Резин мен меншіктердің дұрыс комбинациясын таңдау, подготовка материалдарының жұмыс істейтінін жоғары деңгейде қалыптастыруға маңызды. Әр қолданбалы қажетті қасиеттерге ие болуы мүмкін, мисалы, қашықтық, күштілік немесе термік көршілік, осылайша дағдыларды бағалау керек.

Бірнеше смолалар мен волоқтардың қызметтерін байланыстырушы өнімдердің техникалық деректерін және саладағы кейбір тапсырмаларға негізделген шығармашылық тәжірибелерге айналып, салаларға қарағандағы қажеттілерге сайластыру мүмкіндігі маңызды. Әр түрлі салалардағы қолданбалар әр түрлі қызмет параметрлерін қажет етеді, мысалы, уақытша және авто саласында қызметтердің қажеттілігі әр түрлі.

Жалпы күйде барлық жүктер үшін оптималды layup схемаларын қамтиды

Prepreg таңдау процесінің үшінші қадамы – аралық жүк шарттарына сай болатын, маған mechanical қабілеттерге жетуге көмектесетін layup схемаларын қалайтын. Prepreg материалдарындағы ламинация қатарларының орналасуы composite материалдағы жүктердің қалай бөлінетініне әсер етеді.

Жиілік пен жиіліктің бағытын түсіну структура құрылымының дизайнını оптималастыру үшін маңызды, бұл материалдың күшін арттырады және құрылымдың істемесінің болуы мүмкіндігін кемиді. - Бүгінгі технологиялар - симуляция программасы сияқты - қосымша тәртіптегі дизайндарды оптималастыруға мүмкіндік береді, сонымен қатар композит құрылымдардың дәлдігі мен дизайны қосымша артады.

Соңында, оптимизированные дизайны кез келген түрлі стресс-тесттерді өткізуге болады, бұл жағдайда қалыпты инженерлік стандарттарға және ұшқырлық талаптарға сәйкес ететіндерін тексеру мақсатында. Тесттің басқарымды конфигурацияларын зерттеу арқылы бізге өзгеше prepreg материалдарын бірнеше санаттық қажеттерге және операцияларға сәйкес құрастырылғанын растауға мүмкіндік береді. Бұл да біздің Prepreg қолданбаларына қосылатын авто және ұшақ салалары сияқты секторларға дейін жоғары перформансқа жетуге бағытталған стратегия.

Тамсарлық Prepreg Дамуында Маңызды Факторлер

Искі Қорытындысы және Жинау Циклі Талдауы

Өтір стабильдігі өтір температураларға қарсы көрсететін қолданбалардағы өзгеше prepreg дамуында негізгі ретте маңызды. Prepreg материалдарының термик стресске сай стабильдігі олардың ұшақ және авто қолданбалары сияқты ортақтарда перформансын сақтауға көмектеседі.

Температуралық және уақыттық параметрлерден тұратын өңдеу циклдері, смоланың соңғы қасиеттеріне үлкен әсер етеді. Бұл циклдер предпрег өнімдерінің жалпы қызметкерлігі мен ұзақ жүргізділігін анықтағанда, мәселен, белгілі шарттарға сәйкес келетін қабілеттерге сайлауға мүмкіндік береді. ASTM стандарттары сияқты отрасельдік нормаларға сәйкес қыzu процестерін әртүрлі предпрег формуляциялары үшін дәлберлеуге болады.

Сонымен қатар, пісімден кейінгі өңдеу өзгертулері термік және механикалық қасиеттерді оптималастыруға, әртүрлі салалардағы соңғы өнімдің қуаныштылығын арттыруға мүмкіндік береді.

Жер шарттарына қарсы қарым-қатынасты бекіту

Қоршаған шарттарға табиғатты түрде терең болатын қамтамасыз еткендердің бекітілуін қамтамасыз ету, оңтүстік қамтамасыз еткендердің қолданбаларында маңызды рөл атқарады. Аталған материалдар су, химиялық әсерлер және УФ қызықтыруға қарсы қарым-қатынасты қамтамасыз ету қажет. Смолаларды қамтамасыз етуде экологиялық қызметкерлік практикаларды қолдану, іріктеумен бірге, материалдың табиғатқа қарсы қарым-қатынасты арттыруды да қолдайды.

Жаратылыс сүйкіндігін тексеру – авто және ұлттық кеңес секторларында табылатын коррозиялық аjanдарға дейін болатын prepregs-терді қамтиды. Көшбасшылық қоғамдарына сайLANУ, тамсызған үрдісiн бейнелейді, мәтіндердің қоры және қолданбалары туралы шешімдерді түсіндіреді, сондықтан сайLANDYҚ және қызмет етуді қалыптастыру қажет.

Салмақ және құрылғылық толықтық арасында теңдеу

Салмақ пен құрылғылық толықтық арасындағы мүмкін жеткілікті теңдеу – ұлттық кеңес және авто секторлары сияқты талаптары бар салаларда тамсыз prepreg өңдеу үрдісінде маңызды. Қуаттылыққа қарсы тегістермен жұмыс істей отырып, салмақты кеміту – топырлық және жалпы қызмет етуді жиілдетуге маңызды.

Құрылғылық материалдар талдауы осы өзара қарсы жағдайларды саналып, дизайнерге қандай әріппі, жоғары қабатты prepregs дамытуға қажетті мәліметтерді береді. Өзара қарсы жағдайлар тиімді басқарылса, олар маңызды ақпарат келесі компромисс үшін қолданылатын деректерге айналады. Көптеген, симуляция құралдарының қолданылуы материалдардағы өзгерістерге негізделген қызметкерлік белгілер туралы пронозлы түсінікті береді, бұл дизайны мен материалды таңдауда стратегиялық шешімдерді қоршағанда ақпарат береді.

Предпрег таңдау қиындықтарын жеткізу

Материал қасиеттерінің тұрақтылығын сақтау

Материал қасиеттеріндегі айырмашылықтар предпрег композиттерінің сапы мен қабілеттілігіне құпиялы әсер етуге мүмкіндік береді, сонымен қатар, бұл алаңда тұрақтылық әдетте маңызды. Үшіншілік сапtaғы қабілеттерді тексеру құралдарын қолдану осылайша айырмашылықтарды кемітуге көмектеседі.

Бір қызметкерлік әдіс - басқару және сыйырма испытанияларын пайдалану, ол әр түрлі партиялар арасында қасиеттерді тез түсіндіруге көмектеседі. Мазмұнды қағаздар жинағы мен басты материалдардың ızı traceability-і олардың қасиеттерін сапалы болуын қамтамасыз етуге көмектеседі, әр өнім шығару процесі міндетті техникалық талаптарға сай.

Салыстыру дауысын және сақтау шарттарын басқару

Prepreg материалдарының реактивдігін сақтау үшін дұрыс сақтау шарттары маңызды, температура және сырлық параметрлеріне қатысты атаулы ұйымдастыруларға сай. FIFO (First In, First Out) стратегиясын қолдану материалды пайдалануды оптималаштыруды, қорытындысында қорытындысында қорытындысында қорытындысында қорытындысында қорытындысында қорытындысында қорытындысында қорытындысында.

Изгильдік құралдарды сақтауға дейінгі жобалаушының кеңесіне сай түсіп, прегрейлардың ішкі өмірі мен жұмысқа дайындығын максималдырау мүмкін. Сақталатын материалдарды бастапқы бағалау қажетті есептеледі, олар өндірістік процестің нәтижелеріне әсер етулерінан алдын ала мүмкін жағдайларды анықтау үшін, содан кейін әдетте қалыпты сапарлармен сапасы мен сапалықы қалыптасады.

Уақытша Авиация/Автомобиль Сертификация стандарттарына сәйкес

Авиация мен автомобиль сертификация стандарттарының қиын ландшафтін өткенге болу үшін саламен қатысты регламенттерге толық таным мен ризақлық қажет. Документация мен тесттеу протоколдары FAA және EPA сияқты органдар тарafdан берілген мәнді стандарттарға сәйкес келуі тиіс.

Сертификаттық органдармен күшті қарым-қатынастар қалыптастыру, қажетті рұқсаттарды алу процесін жылдамдауға көмектеседі, осылайша пазарға шығуға мүмкіндік береді. Жаңартылатын сертификация талаптары туралы үздік білім алу маңызды, бұл прегрей продукtlарының қабілетті салалар тарауында қажетті стандарттарға сәйкес келуін қамтамасыз етеді.

Болашақ үрдістер Препрег материалдары Инновация

Улттық Температуралық BMI Резинаның Дамуы

БМИ (бисмалеимид) шынық жүйесі өзгешеуімен жылдам температуралық прегрейк мүмкіндігін береді, осылайша прегрейк материалдардың революциясын әзірлейді, маған аяқтау қолданбалары үшін бірдей жылдам температуралық орталықтарда, мысалы, аероспейс және космос аппараттары. Бұл жаңа шынық дамулері жоғары температурада өмір сүруге арналған, машиналық қасиеттерде жақсылауға болады, оның нәтижесінде іс-әрекет материалдарын қысқартуға болады, сонымен қатар, композиттердің термодинамикалық қабілеттерін жақсырақ етеді.

Бұл даму leading материалдар ғылымы журналдарының зерттеулерімен қолдандырылады, олар БМІ технологияларындағы жалпы прогрессі туралы хабарлайды. Жоғары температурадағы материалдар үшін пазар талаптарын түсіну БМІ шынықтарында инновацияға қол тасынады, ол салыстырмалы қызметкерлік түбірлерін қанағаттандыруға және онынан тыс жеткізу үшін өндірістіктерге мүмкіндік береді.

Тікелей Қайта Өңдеуге Сәйкес Формуласу

Тұрақтылықка айналу маңызы қайта іске асыруға жол ашатын прегрейт формуласуының инновациясына үлкен тәсир етеді. Қоршаған ортаға деген талаптар өзгертілгенде, өндірушілер био-базалы резиндер мен волокндерді қолдануды қосымша кеңейтуді қарастырады. Бұл тұрақты қажеттіліктер прегрейт өндірістің қоршаған ортаға деген әсерін кемітуге бағытталған, бірақ қызметтерді қосымша жоқпаратпа бермейді.

Шығармашылық саласындағы компаниялардың қайта іске асыруға бағытталған серіктестіктері күрделі материалдар секторында қайталанатын экономикалар құруға көмектеседі. Кеңейтілген заңгерлік және пайдаланушылардың басқаруында, компаниялар прегрейт өндірудегі практикасын қырықтай және ресурстарды қамтамасыз ететін әдістермен жаңартуға міндетті.

Дидигальдық двойник интеграциясы қызметтердің нәтижелерін болжау үшін

Диджитал твин технологиясы өндірістің кезінде және эксплуатациялық өмірбаяны boyынша композит материалдарының қабілетін көздей отыру және бейнелеп шығу аралықты өзгертуде ойын ауыстырушы болып табылады. Диджитал твиндерді пайдалану арқылы өндірістік параметрлерді барыншау және продукттың сапасын арттыру үшін мүмкін болатын беделерді анықтау мүмкін.

Бірнеше компаниялар диджитал твин қолданбаларынан туындаған мағаналық тағамдар мен қызметтер туралы кез келген мәліметтер берді. Диджитал технологиялар әлі де дамып жатқанда, оларды композит материалдар өндіріс процестерімен интеграциялау олардың өндірілуі мен пайдалануын қалай өзгертуі мүмкін, бұл жеңілдік және інновацияларға жаңа жолдар ашады.

Сұрақтар мен жауаптар бөлімі

Prepreg материалдары неге тең?

Препрег материалдары резин матрицасымен алдын ала импрегнировданған тәмірлік волокндерден тұратын композиттер. Олар резин міндеттілігі мен су ішкілдігін жеке сақтауға мүмкіндік береді және көршісіз қабілеттері бойынша белгілі.

Космос және автокөбейген салаларында препрегтерді пайдаланудың негізгі плюстары қандай?

Препрегтер салмақ-күш соотношениясын кеміді, олар ыстық емес, бірақ күшті материалдарға жеткізуге дейінгі қолданбалар үшін идеалды. Бұл космос және автокөбейген салаларында горючі қызметтерін және қабілеттерін жақсарту үшін особы жақсы.

Препрег материалдары үшін резин-волокна комбинациялары қалай таңдалады?

Резин және волокна комбинацияларының таңдауы қиырлық, күштілік немесе термік көршілік сияқты қолданба шарттарына байланысты. Сатушы деректер парағы және саламен қатарлары бойынша салыстыру анализі мағыналы шешімдерге келу үшін көмектеседі.

Препрег материалдарындағы инновацияларда қандай жаңа шығындар күтіледі?

Келешектегі тенденциалар ысқын температуралы BMI смоласының формуласын дамыту, переру жағдайына сай prepreg формуласы мен цифрлық двойник технологиясының біріктіруін қамтиды.

Қоршаған ортаға сопеттілік қалай prepreg-ге енгізілетін?

Қоршаған ортаға сопеттілік су, химиялық мәдениеттерге және УФ көтеруіне қарсы стойлы смолаларды пайдалана отырып сақталады. Жаһандық қоршаған ортаға ұшындағы практикаларды қолдану және қоршаған ортаға ұшындағы қарастырмаға тесттерді жүргізу сопеттілікке сай болу үшін маңызды.

Мазмұны

-

Түсіну Препрег материалдары Негізгі қағидалар

- Препрег материалдары неліктен өзара табысты?

- Негізгі компоненттер: Резиналар және волокно толықтырулар

- Саламыстың қажеттіліктерін басқару қажет

- Қадам-қадамды қуыршақтарды бастапқы құру процесі

- Сіздің қызметтік талаптарыңызды таңдау

- Резин-меншік комбинациясын таңдау

- Жалпы күйде барлық жүктер үшін оптималды layup схемаларын қамтиды

- Тамсарлық Prepreg Дамуында Маңызды Факторлер

- Искі Қорытындысы және Жинау Циклі Талдауы

- Жер шарттарына қарсы қарым-қатынасты бекіту

- Салмақ және құрылғылық толықтық арасында теңдеу

- Предпрег таңдау қиындықтарын жеткізу

- Материал қасиеттерінің тұрақтылығын сақтау

- Салыстыру дауысын және сақтау шарттарын басқару

- Уақытша Авиация/Автомобиль Сертификация стандарттарына сәйкес

- Болашақ үрдістер Препрег материалдары Инновация

- Улттық Температуралық BMI Резинаның Дамуы

- Тікелей Қайта Өңдеуге Сәйкес Формуласу

- Дидигальдық двойник интеграциясы қызметтердің нәтижелерін болжау үшін

- Сұрақтар мен жауаптар бөлімі

- Prepreg материалдары неге тең?

- Космос және автокөбейген салаларында препрегтерді пайдаланудың негізгі плюстары қандай?

- Препрег материалдары үшін резин-волокна комбинациялары қалай таңдалады?

- Препрег материалдарындағы инновацияларда қандай жаңа шығындар күтіледі?

- Қоршаған ортаға сопеттілік қалай prepreg-ге енгізілетін?