Landskap Pasaran Serat Karbon Semasa dan Projeksi Pertumbuhan

Nilai Pasaran Global dan Ramalan CAGR (2024-2034)

Industri serat karbon dunia saat ini sedang mengalami pertumbuhan yang sangat pesat akibat meningkatnya permintaan dari pengguna akhir. Menurut perkiraan terbaru, pasar ini diperkirakan bernilai sekitar $8.5 bilion dan harus melanjutkan pertumbuhannya yang kuat setidaknya selama satu dekade. Grand View Research memperkirakan CAGR meningkat menjadi 13.2% antara 2024 dan 2034. Kenaikan ini terutamanya disebabkan oleh perkembangan teknologi serat karbon dan peningkatan aplikasi dalam bidang penerbangan, automotif, dan tenaga renewable. Mereka dianggap sebagai pasaran dengan impak potensial yang besar terhadap pertumbuhan pasaran kerana bahan ringan dan kuat yang mereka perlukan adalah kritikal untuk meningkatkan kecekapan bahan api dan mengurangkan pembebasan gas.

Pemacu Utama: Kembangan Penerbangan dan Pengeluaran EV

Kebutuhan akan serat karbon semakin didukung oleh industri penerbangan kerana dorongan untuk memper ringankan berat supaya dapat menghemat bahan api. Serat karbon sangat kuat dan ringan, menjadikannya bahan yang hebat untuk industri penerbangan. Penggerak pertumbuhan lain (walaupun masih awal) dalam pasaran serat karbon adalah peningkatan pengeluaran kenderaan elektrik (EV). Dalam hal pengurangan berat, EV paling efektif dalam meningkatkan prestasi dan kecekapan, yang merupakan bidang di mana serat karbon menunjukkan kelebihannya. Kajian terkini menunjukkan bahawa penggunaan serat karbon dalam kedua-dua sektor sedang meningkat. Ulasan pakar mencadangkan bahawa pertumbuhan pasaran ini akan terus meningkat dengan laju yang lebih pantas dan penggunaannya akan cepat berkembang untuk menyepadukan teknologi baru.

Pembaruan Teknologi dalam Pengeluaran Serat

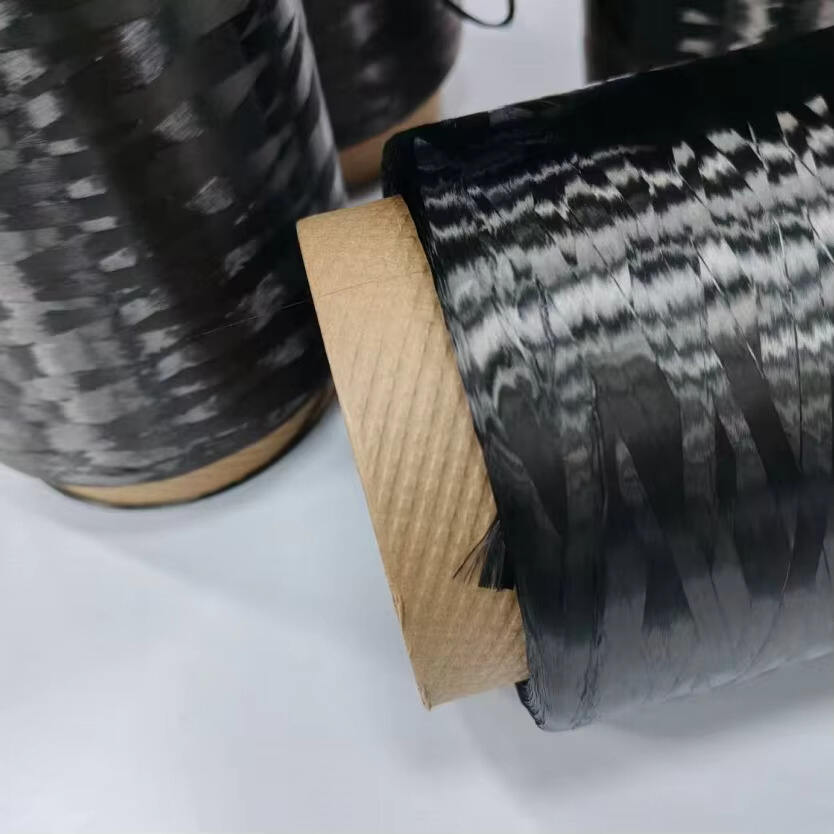

Kemajuan terkini dalam kaedah pengeluaran karbon telah membawa perubahan revolusioner kepada industri: menggunakan arang batu hancur (pitch atau karbon), dan memprosesnya menjadi benang serat karbon, dengan itu meningkatkan keluaran secara drastik dan menghemat kos. Inovasi dalam peralatan pengeluaran automatik dan bahan serat kualiti lebih tinggi telah membaiki kualiti serat keseluruhan dan mengurangkan sisa. Kemajuan ini tidak hanya membaiki kecekapan pengeluaran tetapi juga bergerak menuju kos yang lebih rendah, yang pada gilirannya meningkatkan penggunaan serat karbon di seluruh sektor. Kajian kes menekankan bagaimana organisasi menggunakan perkembangan baru ini untuk mendorong pertumbuhan pasaran, menunjukkan aplikasi yang berkesan yang boleh menurunkan kos pengeluaran dan meningkatkan fungsi produk. Kemajuan ini akan menyumbang kepada penajaan pasaran dan mengukuhkan serat karbon sebagai bahan penting dalam inovasi moden.

Penggunaan Tertentu Industri Memacu Permintaan

Aerospace: Pemeringkatan untuk Kecekapan Bahan Api

Gula Usaha terbaru untuk menggantikan serat karbon, bahan berbasis gula kini digunakan oleh industri penerbangan untuk menciptakan pesawat yang lebih ringan (serat gula lebih ringan 3 hingga 4.5 kali daripada kaca), lebih efisien dan menggunakan bahan bakar lebih sedikit. Penggunaan komposit serat karbon kekuatan tinggi membantu perusahaan penerbangan untuk mengurangi emisi secara signifikan. Berita penerbangan secara rutin melaporkan perubahan ini dari dekoratif ke fungsional dalam bahan pembuatan di mana rasio kekuatan terhadap berat menawarkan keunggulan kinerja dan keberlanjutan yang signifikan. Banyak komposit pesawat masa kini, sistem seperti Boeing 787 Dreamliner atau Airbus A350, bersinar dalam cara mereka menggunakan komposit serat karbon untuk unggul dari pesaing.

Automotif: Serat Karbon dalam Reka Bentuk Kenderaan Elektrik

Industri kereta menggunakan serat karbon untuk mendesain kenderaan elektrik (EV) kerana ia boleh membantu meningkatkan prestasi dengan mengurangkan berat dan memperbaiki prestasi struktur. Faktor ini memberi kesan besar terhadap reka bentuk dan prestasi EV, menjadikannya menarik dan praktikal bagi pengguna. Maklumat ini menyokong evolusi yang konsisten menuju kepada tahap serat karbon yang lebih tinggi dalam reka bentuk EV baru. Sebagai contoh, komponen yang dipadam melalui tekanan untuk kereta mewah kini dibuat dengan mengutamakan ciri-ciri struktur berbanding jisim untuk keupayaan struktur yang tahan lama.

Tenaga Angin: Memperpanjang Kehidupan Bilah Turbin

Komposit Serat Karbon Angin sama bergunanya dalam industri tenaga angin di mana mereka meningkatkan umur dan keawetan bilah turbin. Bahan bio-berdasarkan terkini ini meningkatkan kecekapan dan kelestarian pengeluaran tenaga dan berguna untuk permintaan tenaga hari ini. Penggunaan serat karbon dalam tenaga Renewables semakin bertumbuh, seperti yang ditunjukkan oleh data industri dengan pulangan yang lebih besar pada prestasi turbin. Nisbah kekuatan-berat tinggi karbon digunakan untuk bilah turbin yang tahan lama dengan tahun-tahun perkhidmatan.

Dinamik Pasaran Regional dan Peluang Strategik

Asia-Pasifik: Pusat Pembuatan dan Penindasan Perindustrian Cepat

Asia Pasifik adalah pusat pengeluaran produk serat karbon dan oleh itu memainkan peranan besar dalam pertumbuhan keseluruhan pasaran serat karbon. Kedudukan ini disokong oleh gabungan upah rendah, bantuan kerajaan dan kemajuan teknologi. Dengan China dan Jepun memimpin dalam kapasiti pengeluaran, kawasan ini sedang dalam proses penindasan yang meningkatkan permintaan untuk pasaran serat karbon. Sebagai contoh, kapasiti pengeluaran telah diperluas kerana pengeluaran industri, kilang besar meningkatkan kapasiti pengeluarannya untuk menanggapi permintaan sosial yang meningkat. Pertumbuhan ini terbukti dengan peningkatan kapasiti pengeluaran di kalangan pemain utama di rantau tersebut.

Amerika Utara: Pelaburan dalam R&D Aeronautik

Ketahlian strategik penggunaan serat karbon dalam industri ditegaskan lagi oleh pelaburan R&D yang besar dalam bidang penerbangan di Amerika Utara. Banyak syarikat bekerja dengan universiti dan makmal penyelidikan untuk meluaskan had penggunaan serat karbon. Jenis kemitraan ini amat penting, dan tahap pelaburan adalah tanda positif bagi masa depan serat karbon dan sektor penerbangan. Sebagai contoh, kerjasama antara pemimpin perniagaan dan akademik telah mendorong kemajuan dalam reka bentuk kapal terbang yang ringan dan cekap bahan api, dengan Amerika Utara kini memimpin inovasi ini. Kerja ini menjadi asas kepada satu masa depan cerah bagi aplikasi serat karbon dalam penerbangan.

Eropah: Penggunaan Didorong Kepada Kelestarian dalam Sumber Baru

Kebutuhan serat karbon dalam projek-projek tenaga renewable juga telah dipengaruhi oleh fokus Eropah terhadap kelestarian. Benua ini sangat mengutamakan penyelesaian yang ramah alam serta undang-undang yang ketat, yang mendorong permintaan dan pertumbuhan serat karbon secara khusus dalam aplikasi angin. Ini dipengaruhi oleh dasar-dasar EU dan mereka memacu pelaburan serta pengalihan teknologi untuk serat karbon yang lestari. Menurut statistik, pembiayaan untuk projek tenaga renewable sedang meningkat, dan komposit karbon untuk simpanan tenaga dan perlindungan alam sekitar sejalan dengan trend ini. Pendekatan ini yang berfokus kepada kelestarian menjadikan Eropah sebagai pemimpin dalam projek-projek aplikasi tenaga renewable menggunakan teknologi serat karbon canggih.

Trend Kestabilan Menuba Semula Pengeluaran Serat Karbon

Kemajuan dalam Sistem Daur Ulang Loop-Tertutup

Pembangunan kitaran daur semula tertutup juga memberi impak besar terhadap persekitaran pengeluaran serat karbon dan kecekapan sumber. Ini merupakan sebahagian daripada penyelesaian untuk mendaur semula serat karbon daripada produk EoL untuk menggabungkannya semula dalam produk baru dan mengelakkan pembaziran serta menjaga sumber berharga tersebut. Contohnya, ELG Carbon Fibre Ltd. telah mengambil pendekatan kepada satu sistem kitaran tertutup yang sebenar dengan mengambil balik dan memproses semula serat berkualiti tinggi yang boleh digunakan dalam pelbagai aplikasi untuk mengurangkan jejak karbon di atas persekitaran. Sistem daur semula ini membawa faedah besar kepada industri, tidak hanya untuk menyokong pencapaian matlamat kelestarian tetapi juga untuk meningkatkan kos-efektiviti dengan mengelakkan ketergantungan pada bahan mentah, membawa kepada sumbangan kepada kelestarian keseluruhan pembangunan serat karbon.

Penyedia Bio-Berdasarkan untuk Pengurangan Impak Alam Sekitar

Penggunaan bahan asas bio untuk menghasilkan serat karbon adalah langkah penting menuju pengeluaran yang lebih ramah alam. Bahan dari sumber semula jadi yang terhad dari sumber boleh diperbaharui memberikan faedah yang besar dalam mengurangkan beban alam sekitar keseluruhan bagi serat karbon. Beberapa kajian telah menunjukkan bahawa penggunaan bahan asas bio seperti lignin dan polihidroksialcanoates (PHA) membawa kepada penurunan yang signifikan dalam pelepasan GHE dan permintaan tenaga. Sebagai contoh, syarikat seperti TEIJIN LIMITED sedang mengggunakan pilihan berbasa bio sebagai satu bentuk komitmen kepada kelestarian dan malah membantu mengurangkan impak alam sekitar melalui pengeluaran tradisional serat karbon.

Inisiatif Ekonomi Bulatan oleh Pengeluar Utama

Economy Bulat Ditambahkan kepada Pengeluar Serat Karbon Terkemuka Beberapa pengeluar serat karbon terkemuka telah menerima langkah-langkah ekonomi bulat untuk meningkatkan kelestarian dan mengurangkan sisa. Langkah-langkah ini menilai semula kitaran sumber semasa peringkat pengeluaran dan penggunaan, dengan jumlah paling minimum pelepasan, yang mencerminkan jaminan bagi pengeluaran yang lebih bersih. Syarikat-syarikat, termasuk Toray Industries, telah memulakan aktiviti untuk menyokong penilaian hayat produk dan daur semula sumber, mendirikan sistem daur semula tertutup dan menyokong pengeluaran dengan tumpuan kepada kitaran sumber. Statistik pasaran menunjukkan permintaan yang meningkat dari pelanggan kepada produk ramah alam, membujuk pengeluar untuk membangunkan teknik baru dan menggunakan sumber yang lestari. Dengan menerapkan konsep ekonomi bulat, pengeluar boleh melaksanakan amalan yang lebih lestari dan memenuhi permintaan pelanggan global serta peraturan kerajaan bagi produk hijau.

Soalan Lazim

Berapakah nilai semasa pasaran serat karbon global?

Pasaran serat karbon global bernilai kira-kira USD 8.5 bilion.

Apa sektor-sektor utama yang mendorong pertumbuhan pasaran serat karbon?

Sektor utama yang mendorong pertumbuhan adalah industri penerbangan, kereta, dan tenaga Renewan.

Apakah manfaat utama serat karbon dalam aplikasi penerbangan?

Serat karbon membantu upaya pengurangan berat dan efisiensi bahan bakar, menurunkan emisi dan meningkatkan prestasi.

Bagaimana serat karbon bermanfaat bagi kenderaan elektrik?

Serat karbon menyumbang kepada pengurangan berat dan memperbaiki integriti struktur, meningkatkan prestasi kenderaan elektrik.

Mengapa serat karbon digunakan dalam bilah turbin tenaga angin?

Serat karbon meningkatkan keawetan dan jangka hayat, memperbaiki kecekapan keluaran tenaga dan kelestarian dalam aplikasi tenaga angin.

Jadual Kandungan

- Landskap Pasaran Serat Karbon Semasa dan Projeksi Pertumbuhan

- Penggunaan Tertentu Industri Memacu Permintaan

- Dinamik Pasaran Regional dan Peluang Strategik

- Trend Kestabilan Menuba Semula Pengeluaran Serat Karbon

-

Soalan Lazim

- Berapakah nilai semasa pasaran serat karbon global?

- Apa sektor-sektor utama yang mendorong pertumbuhan pasaran serat karbon?

- Apakah manfaat utama serat karbon dalam aplikasi penerbangan?

- Bagaimana serat karbon bermanfaat bagi kenderaan elektrik?

- Mengapa serat karbon digunakan dalam bilah turbin tenaga angin?