Industri aerospace, automotif, dan pembuatan telah menyaksikan peralihan revolusioner ke arah bahan maju yang memberikan prestasi unggul sambil mengekalkan integriti struktur. Antara bahan inovatif ini, komposit gentian karbon telah muncul sebagai pilihan utama bagi jurutera dan pereka yang ingin mengoptimumkan nisbah berat-kepada-kekuatan serta meningkatkan prestasi produk secara keseluruhan. Transformasi daripada bahan tradisional ini mewakili lebih daripada sekadar kemajuan teknologi; ia menandakan perubahan asas dalam bagaimana industri moden mendekati pemilihan bahan dan pembangunan produk.

Sifat Kekuatan terhadap Berat yang Unggul

Ciri Kekuatan Meregang Luar Biasa

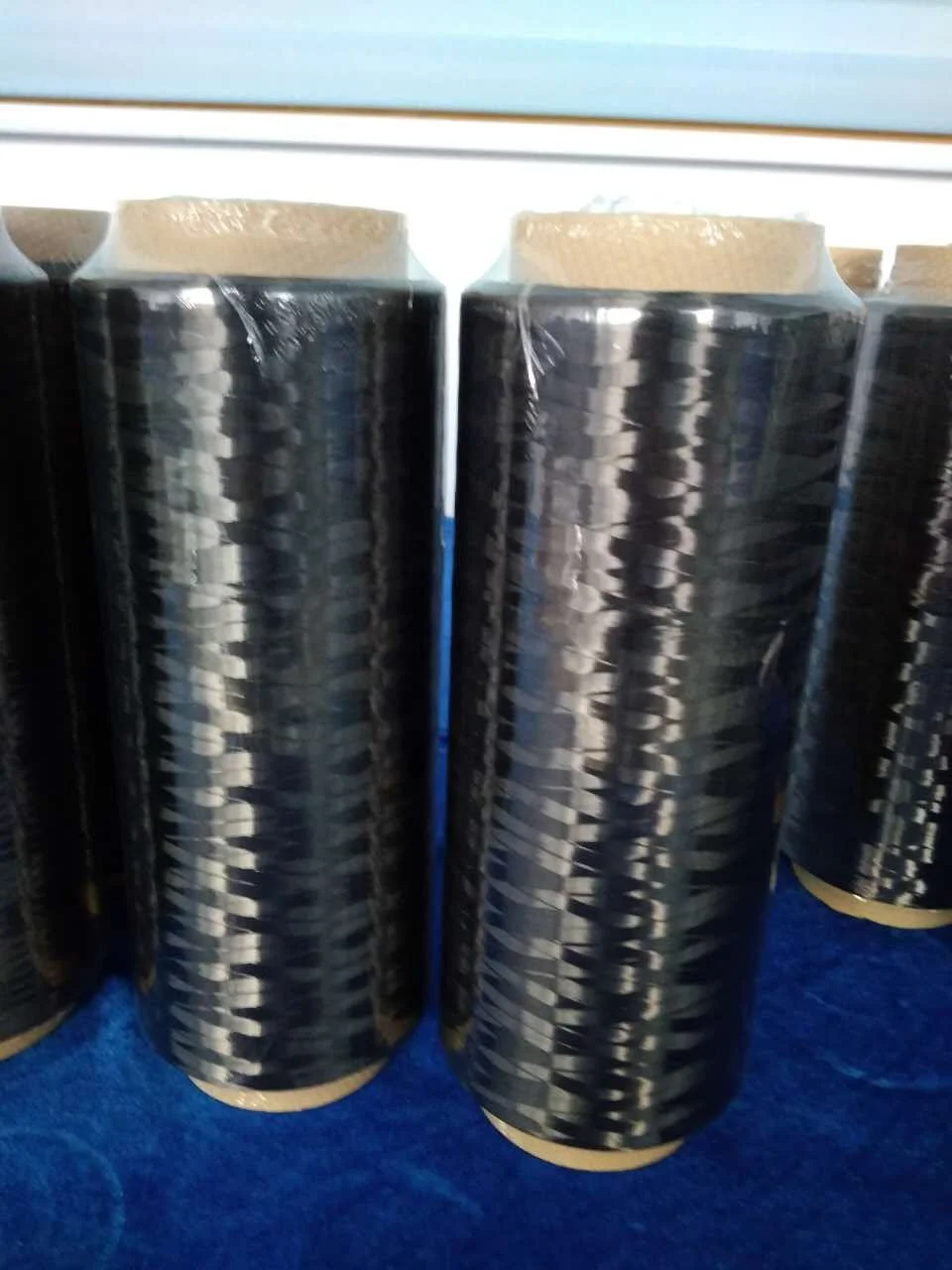

Komposit gentian karbon menunjukkan sifat kekuatan meregang yang luar biasa, jauh melebihi bahan konvensional seperti keluli dan aluminium. Struktur molekul unik gentian karbon, yang terdiri daripada atom karbon yang terikat rapat disusun dalam bentuk hablur, memberikan rintangan luar biasa terhadap daya regangan dan putus. Kekuatan asli ini membolehkan pengilang mencipta komponen yang mampu menahan beban tekanan melampau sambil mengekalkan integriti struktur sepanjang tempoh hayat operasinya.

Kekuatan tegangan komposit gentian karbon berkualiti tinggi biasanya berada dalam julat 3,500 hingga 6,000 MPa, bergantung kepada jenis gentian tertentu dan proses pengilangan yang digunakan. Kekuatan luar biasa ini membolehkan jurutera mereka komponen yang lebih nipis dan ringan tanpa mengorbankan piawaian keselamatan atau prestasi. Industri seperti aerospace dan automotif mendapat manfaat besar daripada ciri ini, memandangkan ia membolehkan penciptaan kenderaan dan kapal terbang yang cekap bahan api namun kekal mempunyai kebolehpercayaan struktur yang unggul.

Kelebihan Reka Bentuk Ringan

Sifat ringan komposit gentian karbon mewakili salah satu kelebihan paling menarik berbanding bahan tradisional. Dengan ketumpatan yang kira-kira 75% lebih rendah daripada keluli dan 35% lebih rendah daripada aluminium, bahan maju ini membolehkan pengurangan berat yang ketara dalam produk siap. Pengurangan berat ini secara langsung diterjemahkan kepada peningkatan kecekapan bahan api, peningkatan keupayaan prestasi, dan pengurangan kos operasi merentasi pelbagai aplikasi.

Proses pembuatan yang menggunakan komposit Serat Karbon boleh mencapai penjimatan berat sehingga 60% berbanding komponen keluli yang setara sambil mengekalkan atau bahkan meningkatkan prestasi struktur. Keupayaan pengurangan berat yang ketara ini telah menjadikan komposit gentian karbon sangat diperlukan dalam aplikasi di mana setiap gram penting, daripada kereta lumba Formula Satu hingga komponen pesawat komersial.

Ketahanan dan Longevity Diperbaiki

Sifat Ketahanan Kakisan

Tidak seperti bahan logam tradisional yang mudah terdedah kepada pengoksidaan dan kakisan, komposit gentian karbon menunjukkan rintangan luar biasa terhadap degradasi persekitaran. Sifat lengai gentian karbon bermaksud ia tidak bertindak balas dengan lembapan, garam, atau kebanyakan bahan kimia, menjadikannya sesuai untuk aplikasi dalam persekitaran yang keras. Rintangan terhadap kakisan ini menghapuskan keperluan bagi salutan pelindung dan mengurangkan keperluan penyelenggaraan jangka panjang secara ketara.

Aplikasi maritim terutamanya mendapat manfaat daripada sifat komposit gentian karbon yang tahan kakisan, memandangkan bahan tradisional kerap mengalami kerosakan akibat pendedahan air masin dan kakisan galvanik. Jangka hayat komponen komposit gentian karbon dalam persekitaran marin boleh melebihi keluli tahan karat sebanyak beberapa dekad, memberikan penjimatan kos yang besar sepanjang kitaran hayat produk. Kemudahan industri yang beroperasi dalam atmosfera kakisan juga memanfaatkan sifat-sifat ini untuk memastikan kebolehpercayaan peralatan dan meminimumkan masa hentian.

Rintangan Kepenatan dan Jangka Hayat Kitaran

Komposit gentian karbon menunjukkan rintangan lesu yang lebih unggul berbanding alternatif logam, mengekalkan sifat mekanikalnya walaupun setelah berjuta-juta kitaran tekanan. Prestasi lesu yang luar biasa ini timbul daripada antara muka gentian-matriks yang berkesan mengagihkan beban dan menghalang perambatan retak. Komponen yang diperbuat daripada komposit gentian karbon mampu menahan keadaan beban berulang tanpa mengalami kelemahan beransur-ansur yang biasanya menjejaskan bahan tradisional.

Jangka hayat lesu bagi struktur komposit gentian karbon yang direka dengan baik kerap kali melebihi komponen aluminium setaraf sebanyak sepuluh kali ganda atau lebih. Jangka hayat operasi yang dipanjangkan ini mengurangkan kekerapan penggantian dan kos penyelenggaraan sambil meningkatkan kebolehpercayaan sistem secara keseluruhan. Industri yang memerlukan aplikasi kitaran tinggi, seperti tenaga angin dan aerospace, sangat bergantung kepada sifat rintangan lesu ini untuk memastikan kejayaan operasi jangka panjang.

Fleksibiliti Reka Bentuk dan Kelebihan Pengilangan

Kemampuan Geometri Kompleks

Proses pembuatan yang berkaitan dengan komposit gentian karbon membolehkan penciptaan geometri kompleks yang sukar atau mustahil dicapai dengan bahan tradisional. Teknik cetakan lanjutan membolehkan jurutera mengintegrasikan pelbagai fungsi ke dalam komponen tunggal, mengurangkan kerumitan pemasangan dan menghapuskan titik kegagalan yang berpotensi. Kebebasan rekabentuk ini membolehkan pengoptimuman bentuk dan fungsi dengan cara yang tidak dapat ditandingi oleh kaedah pembuatan tradisional.

Komposit gentian karbon boleh dibentuk menjadi bentuk rumit dengan ketebalan dinding yang berbeza, pengukuhan bersepadu, dan ciri tertanam semasa proses pembuatan. Keupayaan ini menghapuskan keperluan operasi pemesinan kedua dan prosedur pemasangan, mengurangkan masa dan kos pengeluaran. Keupayaan untuk mencipta struktur berongga dengan geometri dalaman memberikan penjimatan berat tambahan dan peluang integrasi fungsian yang meningkatkan prestasi produk secara keseluruhan.

Ciri mekanikal yang disesuaikan

Salah satu kelebihan paling ketara bagi komposit gentian karbon terletak pada keupayaannya direkabentuk dengan sifat mengikut arah tertentu yang sepadan dengan keperluan beban khusus. Dengan mengawal orientasi gentian dan urutan lapisan, jurutera boleh mengoptimumkan ciri kekuatan dan kekakuan dalam arah yang telah ditentukan. Keupayaan penyesuaian ini membolehkan penggunaan bahan yang lebih cekap serta peningkatan prestasi struktur berbanding bahan tradisional isotropik.

Sifat anisotropik komposit gentian karbon membolehkan pereka meletakkan pengukuhan secara tepat di mana ia paling diperlukan, mencipta struktur yang ringan dan sangat cekap. Pendekatan pengukuhan sasaran ini kontras dengan jelas terhadap bahan tradisional yang memiliki sifat seragam tanpa mengira arah beban. Alat simulasi lanjutan dan teknik pembuatan terus memperluaskan kemungkinan penyesuaian sifat dalam aplikasi komposit gentian karbon.

Pertimbangan Ekonomi dan Alam Sekitar

Analisis Kos Kitaran Hayat

Walaupun kos bahan awal komposit gentian karbon mungkin melebihi bahan tradisional, analisis kos kitar hayat secara menyeluruh kerap menunjukkan kelebihan ekonomi yang ketara. Kombinasi keperluan penyelenggaraan yang berkurangan, jangka hayat perkhidmatan yang lebih panjang, dan peningkatan ciri prestasi biasanya menghasilkan jumlah kos pemilikan yang lebih rendah. Industri yang melabur dalam penyelesaian komposit gentian karbon biasanya mencapai penjimatan besar melalui penggunaan bahan api yang berkurangan, kos penyelenggaraan, dan kekerapan penggantian yang lebih rendah.

Sifat ringan komposit gentian karbon secara langsung memberi jimat kos operasi dalam aplikasi pengangkutan melalui peningkatan kecekapan bahan api. Pengilang pesawat melaporkan penjimatan bahan api sebanyak beberapa peratus apabila menggunakan struktur komposit gentian karbon, yang diterjemahkan kepada jutaan dolar dalam penjimatan operasi sepanjang hayat perkhidmatan pesawat tersebut. Manfaat serupa diperhatikan dalam aplikasi automotif di mana pengurangan berat meningkatkan ekonomi bahan api dan mengurangkan pelepasan.

Keberlanjutan dan Potensi Kitar Semula

Kesan persekitaran komposit gentian karbon terus membaik dengan kemajuan teknologi kitar semula dan proses pengeluaran mampan. Kaedah kitar semula komposit gentian karbon moden boleh memulihara gentian karbon bernilai untuk digunakan semula dalam aplikasi kedua, mengurangkan sisa dan memulihara sumber. Jangka hayat komponen komposit gentian karbon juga menyumbang kepada kelestarian dengan mengurangkan kekerapan penggantian dan kesan pembuatan berkaitan.

Sistem resin berbasis bio yang muncul dan sumber gentian boleh baharu semakin meningkatkan profil alam sekitar komposit gentian karbon. Perkembangan ini, digabungkan dengan proses pemulihan tenaga untuk komponen hujung hayat, menempatkan komposit gentian karbon sebagai alternatif yang semakin mampan berbanding bahan tradisional. Pengurangan pelepasan operasi yang dicapai melalui penjimatan berat kerap kali mengimbangi tenaga terbenam yang lebih tinggi dalam pengeluaran dalam tempoh masa yang relatif singkat.

Penggunaan Industri dan Faedah Prestasi

Aplikasi Aeroangkasa dan Pertahanan

Industri aerospace telah menjadi perintis dalam penggunaan komposit gentian karbon disebabkan ciri prestasi luar biasa dan potensi penjimatan beratnya. Pengilang pesawat komersial kini menggunakan komposit gentian karbon dalam komponen struktur utama, mencapai pengurangan berat yang secara langsung diterjemahkan kepada kecekapan bahan api yang lebih baik dan kapasiti muatan yang meningkat. Aplikasi tentera mendapat manfaat daripada ciri senyap dan rintangan kerosakan pada struktur komposit gentian karbon.

Komposit gentian karbon membolehkan rekabentuk komponen kapal terbang dengan fungsi bersepadu, seperti sifat menyerap radar dan sensor tertanam. Kestabilan dimensi bahan ini di bawah perubahan suhu menjadikannya sesuai untuk aplikasi aerospace yang memerlukan kejituan tinggi di mana had toleransi ketat perlu dikekalkan merentasi julat operasi yang luas. Aplikasi angkasa lepas mendapat manfaat khusus daripada sifat keluaran gas yang rendah serta rintangan terhadap sinaran dalam sistem komposit gentian karbon yang dirumus dengan betul.

Penyelesaian Automotif dan Pengangkutan

Industri automotif semakin bergantung kepada komposit gentian karbon untuk memenuhi peraturan ketat mengenai kecekapan bahan api dan pelepasan sambil mengekalkan piawaian keselamatan. Kenderaan prestasi tinggi menggunakan panel badan dan komponen struktur komposit gentian karbon untuk mencapai nisbah kuasa-kepada-berat dan ciri pengendalian yang optimum. Aplikasi pasaran massa mula muncul apabila kos pembuatan berkurang dan volum pengeluaran meningkat.

Komposit gentian karbon menawarkan ciri penyerapan tenaga pelanggaran yang lebih unggul berbanding bahan tradisional, memberikan perlindungan penghuni yang dipertingkat sambil mengurangkan berat keseluruhan kenderaan. Kebebasan reka bentuk membolehkan penciptaan zon rempuh dan struktur penyerap tenaga yang mengoptimumkan prestasi keselamatan. Pengilang kenderaan elektrik sangat menghargai penjimatan berat yang diberikan oleh komposit gentian karbon, kerana pengurangan berat secara langsung meningkatkan julat bateri dan kecekapan yang lebih baik.

Inovasi Proses Pengeluaran

Teknologi Pengeluaran Maju

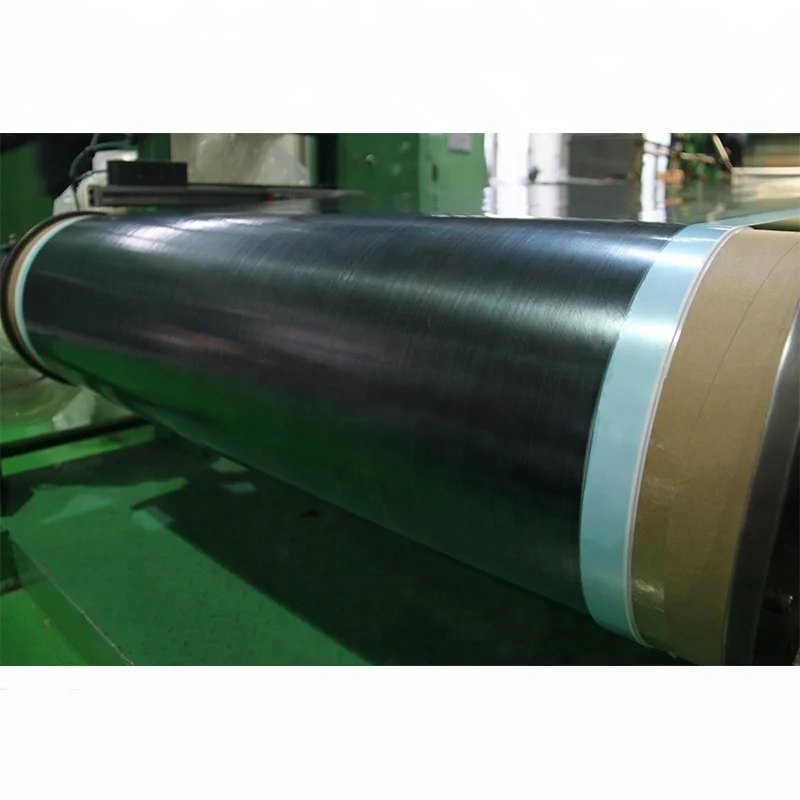

Proses pengeluaran moden untuk komposit gentian karbon telah berkembang bagi membolehkan pengeluaran dalam jumlah besar sambil mengekalkan piawaian kualiti. Sistem penempatan gentian automatik dan teknik acuan pemindahan resin membolehkan pengeluaran komponen komposit gentian karbon yang kompleks secara konsisten dan boleh diulang. Kaedah pengeluaran lanjutan ini mengurangkan kos buruh dan memperbaiki kawalan kualiti berbanding proses susunan tangan tradisional.

Perkembangan proses pemerapan di luar autoklaf telah menjadikan pengeluaran komposit gentian karbon lebih mudah diakses dan berkos rendah untuk pelbagai aplikasi. Teknik-teknik ini mengurangkan penggunaan tenaga dan menghapuskan keperluan kepada peralatan autoklaf yang mahal, sambil tetap menghasilkan komponen berkualiti tinggi. Penambahbaikan berterusan dalam proses pengeluaran terus menurunkan kos dan memperluaskan potensi aplikasi bagi komposit gentian karbon.

Kawalan Kualiti dan Kaedah Ujian

Kaedah ujian bukan merosakkan yang canggih memastikan kualiti dan kebolehpercayaan komponen komposit gentian karbon sepanjang proses pengeluaran. Pemeriksaan ultrasonik, termografi, dan teknik radiografi boleh mengesan kecacatan dalaman dan mengesahkan integriti struktur tanpa merosakkan komponen. Langkah-langkah kawalan kualiti ini memberikan keyakinan terhadap prestasi dan keselamatan produk komposit gentian karbon.

Alat simulasi dan pemodelan lanjutan membolehkan jurutera meramal tingkah laku komposit gentian karbon di bawah pelbagai keadaan beban sebelum pengeluaran bermula. Keupayaan ramalan ini mengurangkan masa dan kos pembangunan sambil mengoptimumkan prestasi reka bentuk. Sistem pemantauan masa nyata semasa pengeluaran boleh mengesan dan membetulkan variasi proses, memastikan kualiti yang konsisten dalam persekitaran pengeluaran.

Soalan Lazim

Apa yang menjadikan komposit gentian karbon lebih kuat daripada keluli tetapi lebih ringan?

Komposit gentian karbon mencapai nisbah kekuatan-kepada-berat yang unggul melalui struktur molekul dan seni bina gentian-matriks yang unik. Gentian karbon individu terdiri daripada atom karbon yang terikat rapat disusun dalam bentuk hablur, memberikan kekuatan tegangan yang luar biasa. Apabila ditanam dalam matriks polimer, gentian ini membentuk bahan komposit yang boleh menjadi hingga lima kali lebih kuat daripada keluli sambil kira-kira 75% lebih ringan. Sifat berarah gentian membolehkan jurutera menempatkan kekuatan secara tepat di mana diperlukan, memaksimumkan kecekapan.

Bagaimanakah komposit gentian karbon rintang kakisan dengan lebih baik berbanding logam tradisional?

Komposit gentian karbon menunjukkan rintangan kakisan yang unggul kerana gentian karbon adalah lengai secara kimia dan tidak bertindak balas dengan lembapan, oksigen, atau kebanyakan bahan kimia industri. Tidak seperti logam yang mengalami tindak balas pengoksidaan yang menyebabkan karat dan kerosakan, komposit gentian karbon mengekalkan integriti struktur mereka dalam persekitaran yang mencabar. Matriks polimer yang mengikat gentian juga memberikan rintangan kimia tambahan, menjadikan bahan ini sesuai untuk aplikasi maritim, pemprosesan kimia, dan luar bangunan di mana bahan tradisional memerlukan salutan pelindung atau penggantian kerap.

Adakah komposit gentian karbon berkesan dari segi kos berbanding bahan tradisional?

Walaupun komposit gentian karbon biasanya mempunyai kos bahan awal yang lebih tinggi berbanding bahan tradisional, mereka sering memberikan nilai unggul melalui analisis kos kitar hayat. Jangka hayat perkhidmatan yang lebih panjang, keperluan penyelenggaraan yang berkurangan, dan faedah operasi seperti penjimatan bahan api kerap kali mengimbangi pelaburan awal yang lebih tinggi. Dalam aplikasi di mana pengurangan berat membawa kepada penjimatan operasi, seperti dalam aerospace dan automotif, komposit gentian karbon boleh memberikan kelebihan ekonomi yang ketara sepanjang tempoh operasinya.

Bolehkah komposit gentian karbon dikitar semula atau dibuang secara mampan?

Ya, komposit gentian karbon boleh dikitar semula melalui beberapa teknologi yang sedang berkembang termasuk pirolisis, solvolisis, dan kaedah kitar semula mekanikal. Proses-proses ini dapat memulihkan gentian karbon untuk digunakan semula dalam aplikasi kedua, walaupun biasanya dengan sedikit pengurangan dalam sifat mekanikal. Industri terus membangunkan kaedah kitar semula yang lebih efisien dan bahan matriks berasaskan bio untuk memperbaiki profil alam sekitar komposit gentian karbon. Selain itu, jangka hayat perkhidmatan yang lebih panjang bagi bahan-bahan ini mengurangkan kekerapan penggantian, menyumbang kepada kelestarian keseluruhan.

Jadual Kandungan

- Sifat Kekuatan terhadap Berat yang Unggul

- Ketahanan dan Longevity Diperbaiki

- Fleksibiliti Reka Bentuk dan Kelebihan Pengilangan

- Pertimbangan Ekonomi dan Alam Sekitar

- Penggunaan Industri dan Faedah Prestasi

- Inovasi Proses Pengeluaran

-

Soalan Lazim

- Apa yang menjadikan komposit gentian karbon lebih kuat daripada keluli tetapi lebih ringan?

- Bagaimanakah komposit gentian karbon rintang kakisan dengan lebih baik berbanding logam tradisional?

- Adakah komposit gentian karbon berkesan dari segi kos berbanding bahan tradisional?

- Bolehkah komposit gentian karbon dikitar semula atau dibuang secara mampan?