The electric vehicle industry is experiencing unprecedented growth, driving manufacturers to seek advanced materials that can enhance performance while reducing weight. Carbon fiber prepreg has emerged as a revolutionary solution that addresses the critical challenges faced by EV producers, offering exceptional strength-to-weight ratios and manufacturing efficiency. This lightweight composite material enables automotive engineers to create structural components that significantly improve battery range and overall vehicle performance. As the demand for sustainable transportation continues to accelerate, integrating carbon fiber prepreg into production processes has become essential for maintaining competitive advantage in the rapidly evolving automotive landscape.

Understanding Carbon Fiber Prepreg Technology in Automotive Applications

Material Composition and Properties

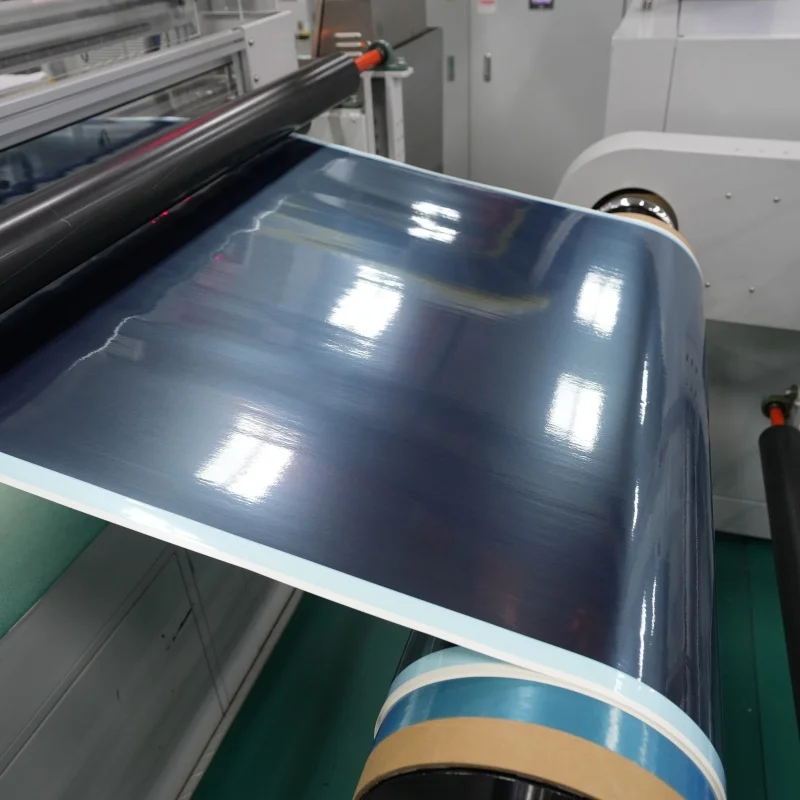

Carbon fiber prepreg represents a sophisticated composite material that combines high-strength carbon fibers with precisely controlled resin systems. The prepreg format eliminates many traditional manufacturing complexities by providing consistent fiber-to-resin ratios and uniform distribution throughout the material structure. This pre-impregnated system ensures optimal mechanical properties while reducing waste and improving quality control during the manufacturing process. The resin matrix, typically epoxy-based, provides excellent adhesion and chemical resistance, making it ideal for automotive environments where durability and performance are paramount.

The unique characteristics of carbon fiber prepreg make it particularly suitable for electric vehicle applications where weight reduction directly impacts battery efficiency and driving range. Unlike traditional materials, this composite offers superior fatigue resistance and dimensional stability under varying temperature conditions. The material maintains its structural integrity across wide temperature ranges, ensuring consistent performance in diverse climatic conditions. These properties become increasingly important as electric vehicles expand into global markets with varying environmental demands.

Manufacturing Process Advantages

The prepreg format significantly streamlines the manufacturing process compared to traditional wet layup methods. Manufacturers can achieve precise thickness control and eliminate the variability associated with manual resin application. This consistency translates to predictable mechanical properties and reduced quality control requirements throughout the production cycle. The material's ready-to-use nature allows for automated layup processes, reducing labor costs and improving production scalability.

Temperature-controlled storage and handling requirements for carbon fiber prepreg ensure material stability and extend shelf life, providing manufacturers with greater flexibility in production planning. The ability to pre-cut and shape components before curing enables complex geometries and integrated designs that would be challenging with traditional manufacturing methods. This flexibility supports the innovative design requirements of electric vehicle platforms while maintaining structural performance standards.

Integration Strategies for Electric Vehicle Production

Structural Component Applications

Electric vehicle manufacturers are increasingly incorporating carbon fiber prepreg into critical structural components where weight reduction provides maximum benefit. Battery enclosures represent one of the most significant opportunities, as reducing structural weight directly improves vehicle range and performance. The material's excellent electromagnetic shielding properties also provide additional benefits for battery protection and electronic interference reduction. These dual advantages make carbon fiber prepreg an ideal choice for next-generation battery management systems.

Body panels and chassis components manufactured from carbon fiber prepreg offer substantial weight savings compared to traditional steel or aluminum alternatives. The material's high stiffness-to-weight ratio enables thinner cross-sections while maintaining structural requirements, creating opportunities for improved interior space and aerodynamic optimization. Advanced manufacturing techniques allow for integrated features and complex geometries that enhance both functionality and aesthetic appeal.

Production Line Integration

Successful integration of carbon fiber prepreg into existing production lines requires careful consideration of processing equipment and workflow optimization. Autoclave curing systems provide the highest quality results, though newer out-of-autoclave processes offer cost-effective alternatives for certain applications. The selection of curing method depends on component geometry, production volume, and quality requirements specific to each application. Manufacturers must balance processing costs with performance requirements to achieve optimal economic outcomes.

Quality control systems must be adapted to accommodate the unique characteristics of carbon fiber prepreg processing. Non-destructive testing methods, including ultrasonic inspection and thermography, ensure structural integrity without compromising production efficiency. Automated inspection systems can be integrated into production lines to maintain consistent quality standards while supporting high-volume manufacturing requirements. These systems provide real-time feedback that enables immediate process adjustments and reduces waste.

Cost-Effectiveness and Economic Considerations

Material Cost Analysis

While carbon fiber prepreg typically commands higher material costs than traditional automotive materials, the total cost of ownership often favors composite solutions when lifecycle benefits are considered. Reduced fuel consumption, extended component life, and improved vehicle performance contribute to overall value propositions that justify initial material investments. The elimination of secondary operations, such as painting and corrosion protection, further enhances economic attractiveness for many applications.

Volume production strategies can significantly impact material costs through supplier partnerships and long-term procurement agreements. Manufacturers investing in carbon fiber prepreg technology often benefit from economies of scale as production volumes increase. The development of regional supply chains and strategic partnerships with prepreg manufacturers helps stabilize pricing while ensuring consistent material availability for production planning.

Manufacturing Efficiency Gains

The inherent properties of carbon fiber prepreg enable significant manufacturing efficiencies that offset higher material costs. Reduced processing steps, elimination of secondary finishing operations, and improved dimensional accuracy contribute to lower labor costs and reduced cycle times. These efficiency gains become more pronounced as production volumes increase and manufacturing processes mature. Automated handling systems further enhance productivity while maintaining consistent quality standards.

Waste reduction represents another significant economic advantage of carbon fiber prepreg integration. The precise material distribution and controlled resin content minimize excess material and reduce disposal costs. Recycling opportunities for carbon fiber waste streams are expanding, creating additional value recovery options for manufacturers. These environmental benefits align with sustainability goals while providing tangible economic returns through waste reduction and recycling revenue.

Technical Implementation Guidelines

Design Optimization Strategies

Effective integration of carbon fiber prepreg requires design approaches that maximize material advantages while accommodating manufacturing constraints. Fiber orientation optimization ensures that material properties align with load requirements, maximizing structural efficiency while minimizing material usage. Advanced simulation tools enable engineers to predict performance characteristics and optimize designs before physical prototyping, reducing development time and costs.

Multi-functional design approaches leverage the unique properties of carbon fiber prepreg to integrate multiple functions into single components. This consolidation reduces assembly complexity, improves reliability, and creates opportunities for weight reduction beyond simple material substitution. Design for manufacturing principles must be applied early in the development process to ensure compatibility with production capabilities and quality requirements.

Quality Assurance Protocols

Implementing robust quality assurance protocols is essential for successful carbon fiber prepreg integration in automotive applications. Process monitoring systems track critical parameters including temperature, pressure, and cure profiles to ensure consistent component quality. Statistical process control methods help identify trends and prevent quality issues before they impact production efficiency or component performance.

Material traceability systems ensure that carbon fiber prepreg lots can be tracked throughout the supply chain and into finished components. This capability supports warranty requirements and enables rapid response to quality issues if they occur. Documentation systems must capture all relevant processing parameters and inspection results to support continuous improvement initiatives and regulatory compliance requirements.

Future Trends and Market Developments

Technology Advancement Trajectories

The carbon fiber prepreg industry continues to evolve with developments in fiber technology, resin systems, and manufacturing processes. Next-generation fibers offer improved properties while reducing costs, making composite solutions more accessible for high-volume automotive applications. Resin system improvements focus on faster cure cycles, improved toughness, and enhanced environmental resistance to meet demanding automotive requirements.

Automated manufacturing technologies are expanding capabilities for carbon fiber prepreg processing, including automated tape laying, fiber placement, and integrated quality control systems. These technologies reduce labor requirements while improving consistency and enabling complex geometries that were previously impractical. The integration of artificial intelligence and machine learning technologies promises further improvements in process optimization and quality prediction.

Market Growth Projections

Industry analysts project substantial growth in carbon fiber prepreg applications within the electric vehicle sector as production volumes increase and material costs continue to decline. Market expansion is driven by regulatory pressure for improved fuel efficiency, consumer demand for performance, and manufacturer competition for technological differentiation. This growth creates opportunities for supply chain development and manufacturing capacity expansion.

Regional market development varies based on local automotive industry capabilities and government policies supporting electric vehicle adoption. Manufacturers are establishing regional production capabilities to serve local markets while reducing transportation costs and improving supply chain resilience. These developments support the broader adoption of carbon fiber prepreg technology across diverse automotive applications.

FAQ

What are the main advantages of using carbon fiber prepreg in electric vehicle production

Carbon fiber prepreg offers significant weight reduction compared to traditional materials, directly improving electric vehicle range and performance. The material provides exceptional strength-to-weight ratios, enabling thinner structural sections while maintaining safety requirements. Additionally, the prepreg format ensures consistent quality and reduces manufacturing variability compared to wet layup processes. The electromagnetic shielding properties also protect sensitive electronic components from interference.

How does carbon fiber prepreg processing differ from traditional composite manufacturing

Carbon fiber prepreg eliminates the need for manual resin application during manufacturing, as the fibers are pre-impregnated with precisely controlled resin content. This approach provides better fiber-to-resin ratios, reduces waste, and improves dimensional consistency. The material requires temperature-controlled storage and specific curing processes, but these requirements are offset by improved quality control and reduced processing steps compared to wet layup methods.

What factors should manufacturers consider when integrating carbon fiber prepreg into production lines

Key considerations include curing equipment capabilities, quality control systems, material handling requirements, and workforce training needs. Manufacturers must evaluate their existing production infrastructure and determine necessary upgrades or modifications. Volume requirements, component geometry, and quality standards influence processing method selection and equipment investments. Long-term material supply agreements and cost projections should also factor into integration planning.

How do cost considerations compare between carbon fiber prepreg and traditional automotive materials

While carbon fiber prepreg typically has higher initial material costs, the total cost of ownership often favors composite solutions when considering manufacturing efficiencies, performance benefits, and lifecycle costs. Reduced processing steps, elimination of secondary operations, and improved fuel efficiency contribute to overall value propositions. As production volumes increase and technology advances, material costs continue to decline, improving economic attractiveness for automotive applications.

Table of Contents

- Understanding Carbon Fiber Prepreg Technology in Automotive Applications

- Integration Strategies for Electric Vehicle Production

- Cost-Effectiveness and Economic Considerations

- Technical Implementation Guidelines

- Future Trends and Market Developments

-

FAQ

- What are the main advantages of using carbon fiber prepreg in electric vehicle production

- How does carbon fiber prepreg processing differ from traditional composite manufacturing

- What factors should manufacturers consider when integrating carbon fiber prepreg into production lines

- How do cost considerations compare between carbon fiber prepreg and traditional automotive materials