Mastering Advanced Composite Manufacturing with Fiberglass Prepreg

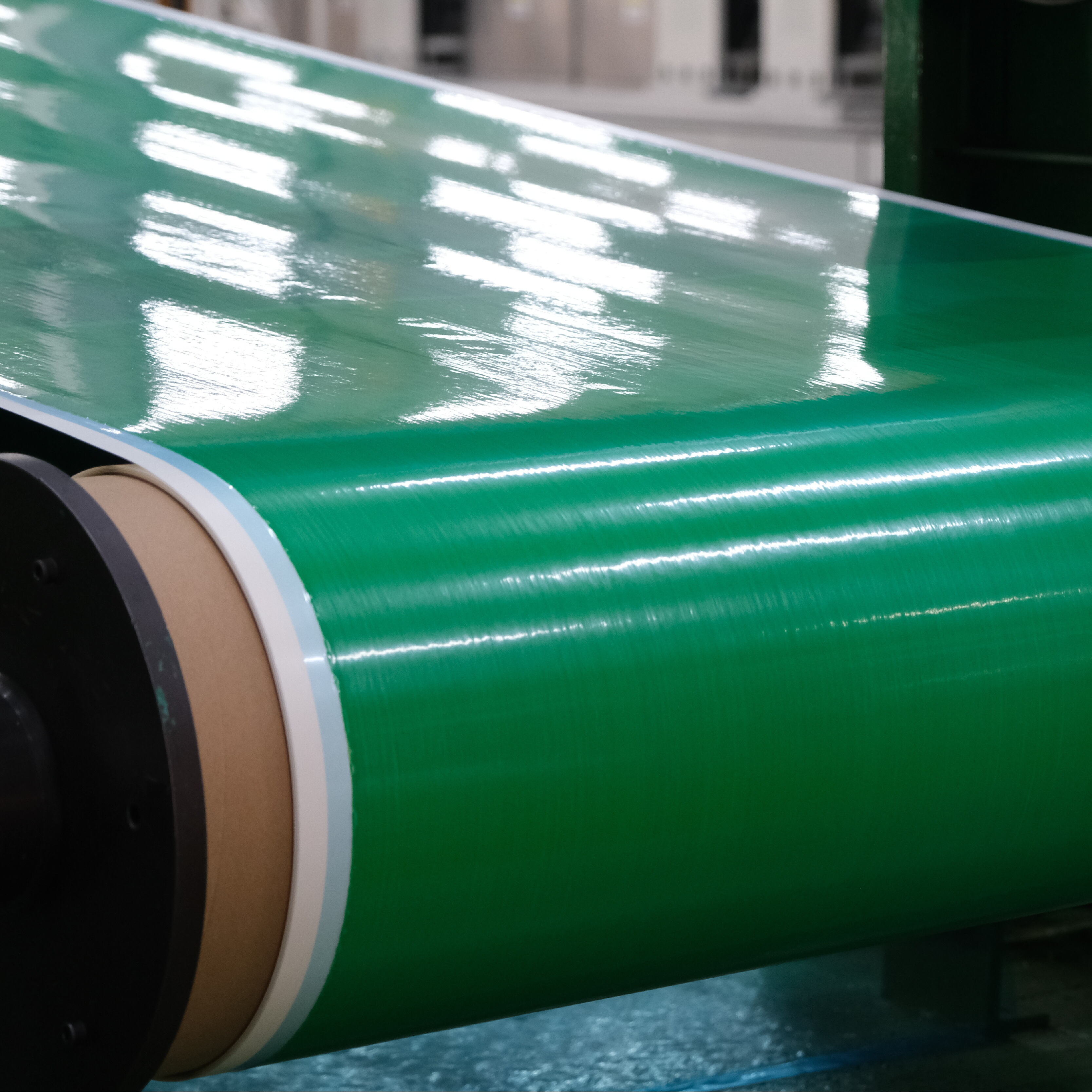

Fiberglass prepreg has revolutionized composite manufacturing across aerospace, automotive, and marine industries. This advanced material, consisting of fiberglass reinforcement pre-impregnated with resin systems, offers exceptional strength-to-weight ratios and consistent material properties. Understanding how to work with fiberglass prepreg effectively is crucial for achieving optimal results in composite part production.

Modern manufacturing demands increasingly sophisticated materials, and fiberglass prepreg stands at the forefront of composite innovation. Its pre-impregnated nature ensures precise resin content and eliminates the messy hand lay-up processes associated with traditional composite manufacturing. However, success with this material requires attention to detail and adherence to specific handling and processing guidelines.

Essential Storage and Handling Guidelines

Temperature Control and Storage Requirements

Proper storage of fiberglass prepreg is fundamental to maintaining its quality and processability. These materials typically require storage at temperatures between -18°C and -23°C (0°F to -10°F) to prevent premature curing. When removing fiberglass prepreg from cold storage, it's essential to allow it to thaw completely before opening the sealed packaging to prevent moisture contamination from condensation.

The working life of fiberglass prepreg at room temperature, also known as out-time, varies depending on the resin system but typically ranges from 7 to 30 days. Maintaining detailed records of material out-time is crucial for ensuring optimal performance and preventing waste.

Material Handling Best Practices

When handling fiberglass prepreg, wearing clean, lint-free gloves is mandatory to prevent contamination and ensure worker safety. The material should be handled gently to avoid distorting the fiber orientation or creating wrinkles. During cutting and layup, maintaining a clean work environment is crucial as any foreign particles can compromise the final part's integrity.

Proper tools, including sharp scissors or utility knives designed for composite materials, help ensure clean cuts without fraying. Using release films and peel plies appropriately during layup will facilitate easier processing and better surface finish.

Layup and Processing Techniques

Professional Layup Methodology

Successful layup of fiberglass prepreg begins with careful planning of ply orientation and sequence. Each layer should be applied with consistent pressure to remove any trapped air and ensure proper consolidation. The use of debulking techniques between layers can significantly improve laminate quality, especially for complex parts or thick sections.

When working with multiple plies, stagger splice points and overlaps to prevent stress concentrations in the final part. Proper alignment of fibers is critical, as misalignment can significantly reduce the mechanical properties of the finished component.

Advanced Processing Parameters

Processing fiberglass prepreg typically involves autoclave or out-of-autoclave curing cycles. Temperature ramps, pressure applications, and dwell times must be carefully controlled according to the material manufacturer's specifications. Vacuum bagging techniques require attention to detail, ensuring proper placement of breather and bleeder materials for optimal resin flow and air removal.

Modern processing methods may incorporate automated systems for temperature and pressure control, helping achieve consistent results across production runs. Monitoring cure cycles through thermocouples and pressure sensors provides valuable data for quality control and process optimization.

Quality Control and Testing Methods

Visual Inspection Protocols

Quality control begins with visual inspection during all stages of processing. Look for consistent fiber orientation, absence of wrinkles or bridging, and proper consolidation between layers. Surface appearance should be uniform, with no dry spots or resin-rich areas visible.

Documentation of visual inspections, including photographs of critical areas and detailed notes, helps maintain quality standards and provides traceability for each production run.

Advanced Testing Requirements

Beyond visual inspection, various testing methods ensure the quality of fiberglass prepreg parts. These may include ultrasonic testing for void content, mechanical testing for strength and stiffness properties, and thermal analysis to verify proper cure. Implementing a comprehensive testing program helps identify potential issues early in the production process.

Regular calibration of processing equipment and validation of test methods ensure consistent quality control measures across production runs. Maintaining detailed records of test results helps track material and process performance over time.

Frequently Asked Questions

What is the typical shelf life of fiberglass prepreg?

The shelf life of fiberglass prepreg, when stored at recommended temperatures (-18°C to -23°C), typically ranges from six months to one year. However, this can vary depending on the specific resin system and storage conditions. Always check the manufacturer's specifications and maintain proper documentation of storage times.

How can I optimize vacuum bagging for fiberglass prepreg?

Successful vacuum bagging requires careful material selection and placement. Use appropriate release films, breather materials, and high-quality vacuum bagging films. Ensure proper overlap of vacuum bag sealant tape, strategic placement of vacuum ports, and thorough leak checking before processing. Consider using corner pleats for complex geometries to prevent bridging.

What are the common defects in fiberglass prepreg processing and how to avoid them?

Common defects include void formation, delamination, and improper cure. Prevent these issues by maintaining proper storage conditions, following recommended handling procedures, and carefully controlling processing parameters. Regular quality control checks and proper training of personnel are essential for minimizing defects in production.