Understanding the Revolutionary Impact of Fiberglass Prepreg Technology in Marine Manufacturing

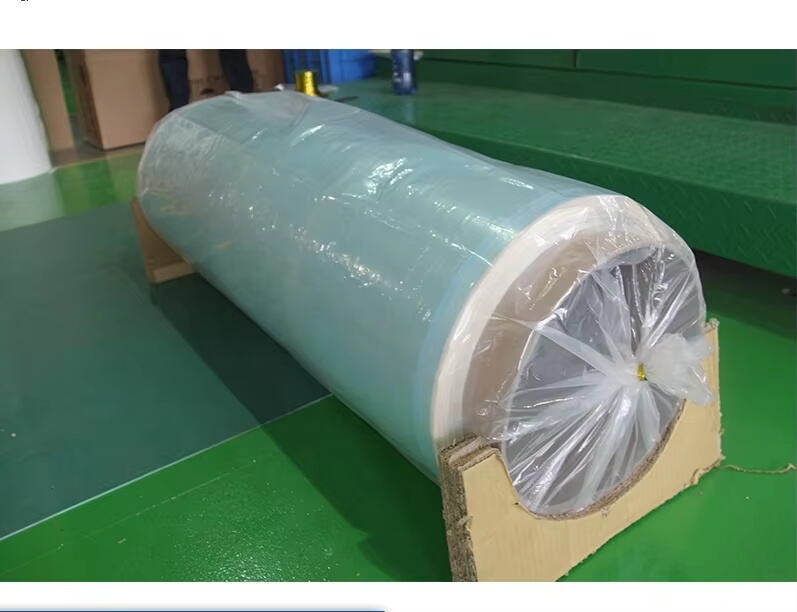

The marine industry has witnessed a remarkable transformation in boat building and vessel construction techniques over recent decades. At the forefront of this evolution stands fiberglass prepreg, a sophisticated composite material that combines high-performance glass fibers with precisely controlled resin content. This advanced material has revolutionized how marine vessels are manufactured, offering unprecedented advantages in strength, durability, and overall performance.

As maritime manufacturers increasingly embrace fiberglass prepreg technology, the industry continues to discover new possibilities for creating lighter, stronger, and more efficient marine vessels. From luxury yachts to high-performance racing boats, this innovative material has become an integral component in modern marine construction, setting new standards for quality and reliability on the water.

Core Advantages of Fiberglass Prepreg in Marine Construction

Superior Strength-to-Weight Characteristics

One of the most compelling attributes of fiberglass prepreg in marine applications is its exceptional strength-to-weight ratio. The precisely controlled resin content ensures optimal fiber-to-resin distribution, resulting in structures that are remarkably strong yet significantly lighter than traditional materials. This weight reduction translates directly into improved fuel efficiency and enhanced vessel performance.

Marine vessels constructed with fiberglass prepreg can achieve structural integrity comparable to steel while weighing considerably less. This characteristic proves particularly valuable in high-performance boats and racing vessels where every pound matters. The reduced weight also allows for increased payload capacity without compromising the vessel's structural integrity.

Enhanced Durability and Weather Resistance

The marine environment presents numerous challenges to vessel materials, including constant exposure to saltwater, UV radiation, and varying temperatures. Fiberglass prepreg demonstrates superior resistance to these harsh conditions, maintaining its structural properties over extended periods. The pre-impregnated nature of the material ensures consistent resin distribution, creating a more robust barrier against environmental factors.

The material's resistance to corrosion and degradation significantly extends the lifespan of marine vessels, reducing maintenance requirements and associated costs. Unlike traditional materials that may require frequent treatments or replacements, fiberglass prepreg maintains its integrity and appearance with minimal upkeep.

Manufacturing Efficiency and Quality Control

Streamlined Production Processes

The use of fiberglass prepreg in marine manufacturing introduces significant efficiencies to the production process. The pre-impregnated nature of the material eliminates the need for manual resin application, reducing labor costs and minimizing the potential for human error. This standardization results in more consistent product quality and reduced manufacturing time.

Modern marine manufacturers can achieve precise control over material properties, ensuring each component meets exact specifications. The controlled resin content also minimizes waste and excess weight, contributing to both environmental sustainability and cost efficiency in production.

Advanced Quality Assurance

Quality control in marine manufacturing reaches new heights with fiberglass prepreg technology. The material's uniform composition allows for detailed inspection and testing at every stage of production. Manufacturers can verify structural integrity through non-destructive testing methods, ensuring each component meets rigorous marine safety standards.

The predictable behavior of fiberglass prepreg enables engineers to design with greater precision and confidence. This reliability translates into safer, more dependable vessels that consistently meet or exceed industry regulations and classification society requirements.

Environmental and Economic Implications

Sustainable Manufacturing Practices

As environmental consciousness grows within the marine industry, fiberglass prepreg offers significant advantages in sustainable manufacturing. The precise material control reduces waste during production, while the lighter weight of finished vessels contributes to reduced fuel consumption and lower emissions throughout their operational life.

The durability of fiberglass prepreg also means fewer replacements and repairs over time, reducing the overall environmental impact of vessel maintenance. Additionally, many manufacturers are now developing recycling programs for end-of-life composite materials, further enhancing the environmental credentials of fiberglass prepreg applications.

Long-term Cost Benefits

While the initial investment in fiberglass prepreg technology may be higher than traditional materials, the long-term economic benefits are substantial. Reduced maintenance requirements, extended service life, and improved fuel efficiency contribute to significantly lower total ownership costs over the vessel's lifetime.

The material's reliability also helps maintain higher resale values for marine vessels, providing better return on investment for owners. These economic advantages, combined with the superior performance characteristics, make fiberglass prepreg an increasingly attractive choice for marine applications.

Future Developments and Innovations

Emerging Technologies

The future of fiberglass prepreg in marine applications continues to evolve with ongoing research and development. Advanced manufacturing techniques, such as automated layup systems and real-time cure monitoring, are enhancing production efficiency and quality control even further.

Innovations in fiber technology and resin chemistry are pushing the boundaries of what's possible with fiberglass prepreg. These developments promise even lighter, stronger, and more versatile materials for next-generation marine vessels.

Industry Integration

As the marine industry embraces digital transformation, fiberglass prepreg technology is becoming increasingly integrated with smart manufacturing systems. This integration enables more precise control over production processes and opens new possibilities for customization and optimization.

The growing adoption of fiberglass prepreg across different vessel types is driving standardization and best practices in marine manufacturing, contributing to improved industry-wide quality and safety standards.

Frequently Asked Questions

How does fiberglass prepreg compare to traditional fiberglass in marine applications?

Fiberglass prepreg offers superior strength, consistency, and quality control compared to traditional fiberglass. The pre-impregnated nature ensures optimal resin content and distribution, resulting in stronger, lighter structures with better long-term performance.

What maintenance requirements do vessels built with fiberglass prepreg have?

Vessels constructed with fiberglass prepreg typically require less maintenance than those built with traditional materials. Regular cleaning and inspection are recommended, but the material's inherent durability and weather resistance minimize the need for frequent repairs or treatments.

Is fiberglass prepreg suitable for all types of marine vessels?

While fiberglass prepreg offers significant advantages for many marine applications, its suitability depends on specific vessel requirements, operating conditions, and budget considerations. It is particularly beneficial for performance vessels, luxury yachts, and applications where weight reduction and durability are crucial factors.

Table of Contents

- Understanding the Revolutionary Impact of Fiberglass Prepreg Technology in Marine Manufacturing

- Core Advantages of Fiberglass Prepreg in Marine Construction

- Manufacturing Efficiency and Quality Control

- Environmental and Economic Implications

- Future Developments and Innovations

- Frequently Asked Questions