The Revolutionary Impact of Advanced Composites in Modern Transportation

The transportation industry has witnessed a remarkable transformation with the widespread adoption of carbon fiber panels across aerospace and automotive applications. These lightweight yet incredibly strong composite materials have revolutionized how manufacturers approach vehicle design and performance optimization. From commercial aircraft to high-performance sports cars, carbon fiber panels have become the material of choice for engineers and designers seeking to push the boundaries of what's possible in transportation technology.

The aerospace and automotive sectors have embraced carbon fiber panels for their exceptional strength-to-weight ratio, superior durability, and remarkable versatility. As industries increasingly prioritize fuel efficiency and environmental sustainability, these advanced materials have proven instrumental in achieving these crucial objectives while maintaining the highest safety and performance standards.

Advanced Material Properties and Performance Benefits

Unmatched Strength and Weight Reduction

Carbon fiber panels exhibit extraordinary mechanical properties that make them ideal for transportation applications. These composite materials offer strength comparable to steel while weighing significantly less – typically about one-fourth the weight of traditional steel components. This remarkable strength-to-weight ratio enables manufacturers to create vehicles that are simultaneously lighter and more robust than their conventional counterparts.

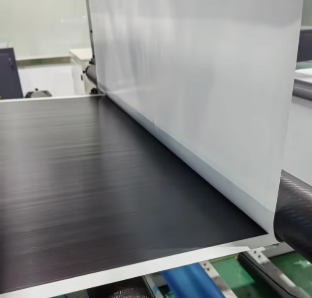

The structural integrity of carbon fiber panels comes from their unique composition of carbon fiber filaments embedded in a polymer matrix. This construction provides exceptional resistance to tension, compression, and bending forces, making them perfect for critical structural components in both aircraft and automobiles.

Superior Durability and Fatigue Resistance

One of the most compelling advantages of carbon fiber panels is their outstanding resistance to fatigue and environmental degradation. Unlike traditional materials that may weaken over time due to repeated stress cycles, carbon fiber composites maintain their structural properties throughout their service life. This exceptional durability translates to longer-lasting components and reduced maintenance requirements.

The material's inherent resistance to corrosion and chemical degradation further enhances its longevity, particularly in demanding aerospace applications where exposure to extreme temperatures and atmospheric conditions is common. This durability factor has made carbon fiber panels increasingly attractive for both commercial and military aircraft manufacturers.

Environmental and Economic Implications

Fuel Efficiency and Emissions Reduction

The implementation of carbon fiber panels in transportation design has led to significant improvements in fuel efficiency. In the automotive sector, reducing vehicle weight by just 10% can result in fuel consumption savings of 6-8%. This weight reduction becomes even more impactful in aerospace applications, where every pound saved translates to substantial fuel savings over an aircraft's operational lifetime.

The environmental benefits extend beyond fuel efficiency. The reduced weight means vehicles require less energy to operate, resulting in lower carbon emissions. This aligns perfectly with increasingly stringent environmental regulations and growing consumer demand for more sustainable transportation options.

Long-term Cost Benefits

While the initial cost of carbon fiber panels may be higher than traditional materials, the long-term economic advantages are compelling. The reduced fuel consumption, lower maintenance requirements, and extended service life often result in significant cost savings over time. For commercial airlines, these savings can amount to millions of dollars per aircraft over its operational lifespan.

Additionally, the manufacturing processes for carbon fiber panels continue to evolve, becoming more efficient and cost-effective. This trend is driving down production costs while maintaining the superior quality and performance characteristics that make these materials so valuable.

Manufacturing and Implementation Challenges

Production Complexity and Innovation

The manufacturing of carbon fiber panels requires sophisticated processes and specialized expertise. The production involves carefully layering carbon fiber sheets, applying resin matrices, and utilizing precise curing procedures under controlled conditions. While these requirements present certain challenges, they have also driven innovation in manufacturing technologies and processes.

Advanced automation systems and quality control measures have been developed to ensure consistent production of high-quality carbon fiber panels. These technological advances continue to improve manufacturing efficiency while reducing production costs and maintaining the exceptional standards required for aerospace and automotive applications.

Integration and Design Considerations

Implementing carbon fiber panels in vehicle design requires careful consideration of various factors, including structural integration, thermal expansion properties, and repair procedures. Engineers must account for these elements during the design phase to ensure optimal performance and maintainability of the final product.

The industry has developed specialized techniques for joining carbon fiber panels with other materials and creating hybrid structures that maximize the benefits of different materials in specific applications. These innovations have expanded the possibilities for carbon fiber panel usage in both aerospace and automotive designs.

Future Trends and Developments

Emerging Technologies and Applications

The future of carbon fiber panels in transportation looks increasingly promising as new technologies and applications emerge. Researchers are developing advanced manufacturing techniques, including 3D printing of carbon fiber composites, which could revolutionize how these materials are produced and implemented.

Smart materials incorporating carbon fiber panels with integrated sensors and monitoring capabilities are also under development. These innovations could enable real-time structural health monitoring and predictive maintenance, further enhancing the safety and reliability of aerospace and automotive applications.

Market Growth and Industry Adoption

The global market for carbon fiber panels continues to expand as more manufacturers recognize their benefits. The automotive industry, in particular, is increasing its adoption of these materials beyond high-end sports cars to include more mainstream vehicles. This broader implementation is driving further innovations in production efficiency and cost reduction.

As environmental regulations become stricter and the demand for sustainable transportation solutions grows, the role of carbon fiber panels in both aerospace and automotive applications is expected to become even more significant.

Frequently Asked Questions

How do carbon fiber panels compare to traditional materials in terms of safety?

Carbon fiber panels often exceed the safety performance of traditional materials due to their superior strength and energy absorption capabilities. They can be engineered to create stronger crash structures while maintaining lighter weight, providing better protection in impact situations.

What is the typical lifespan of carbon fiber panels in vehicles?

When properly maintained, carbon fiber panels can last the entire lifetime of a vehicle without significant degradation. Their resistance to fatigue, corrosion, and environmental factors contributes to their exceptional longevity, often exceeding 20-30 years in normal operating conditions.

Are carbon fiber panels environmentally sustainable?

While the production of carbon fiber panels requires more energy than traditional materials, their lightweight properties lead to significant fuel savings and reduced emissions over their lifetime. Additionally, research is ongoing into recycling methods and more sustainable production processes to further improve their environmental impact.