The Revolutionary Impact of Advanced Composites in Aviation

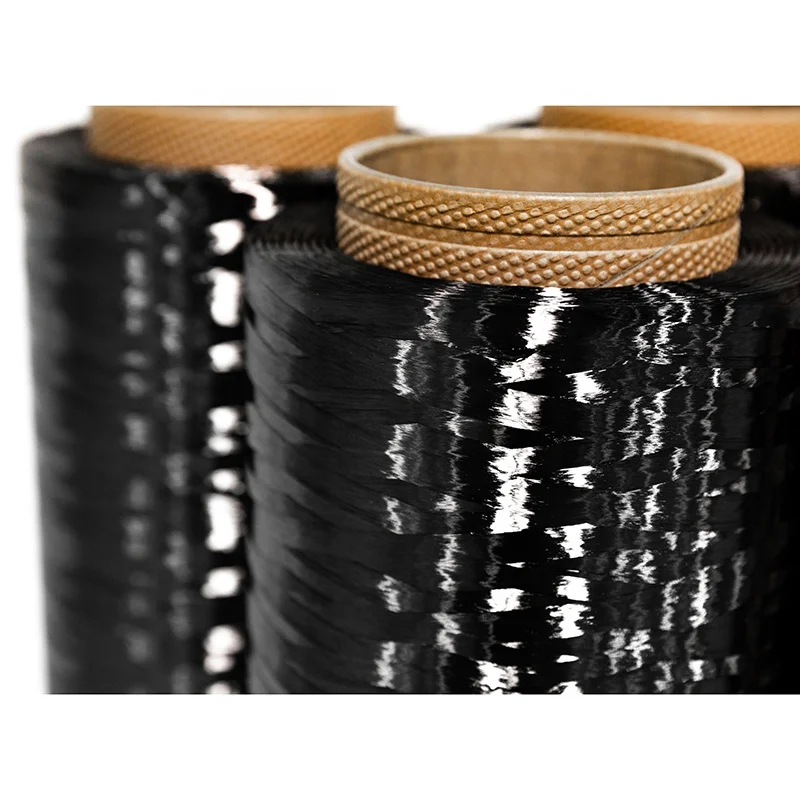

The aviation industry has undergone a dramatic transformation over the past few decades, largely due to the introduction and widespread adoption of aircraft carbon fiber materials. These advanced composites have revolutionized how modern aircraft are designed, built, and operated, marking a significant leap forward in aviation technology. From commercial airliners to military jets, the implementation of carbon fiber has become a cornerstone of contemporary aircraft construction, offering unprecedented advantages in terms of safety, performance, and efficiency.

Modern aircraft manufacturers increasingly rely on carbon fiber reinforced polymers (CFRP) to create stronger, lighter, and more durable aircraft components. This shift from traditional metallic materials to aircraft carbon fiber has not only enhanced structural integrity but has also contributed to improved fuel efficiency and reduced maintenance requirements. The aviation industry's commitment to safety and innovation continues to drive the development and application of these advanced materials.

Engineering Excellence Through Composite Materials

Superior Structural Properties

Aircraft carbon fiber composites demonstrate exceptional strength-to-weight ratios that far surpass traditional aerospace materials. These advanced materials can be engineered to be five times stronger than steel while weighing significantly less. The unique molecular structure of carbon fiber allows it to withstand extreme forces and environmental conditions, making it ideal for critical aircraft components such as wings, fuselage sections, and tail assemblies.

The durability of aircraft carbon fiber extends beyond mere strength. These materials exhibit remarkable fatigue resistance, meaning they can endure repeated stress cycles without developing the microscopic cracks that often plague metal components. This inherent resistance to fatigue contributes significantly to the overall safety and longevity of modern aircraft.

Weight Reduction Benefits

One of the most significant advantages of aircraft carbon fiber is its ability to substantially reduce aircraft weight without compromising structural integrity. Modern commercial aircraft can achieve weight reductions of up to 20% through the strategic use of carbon fiber composites. This weight reduction translates directly into improved fuel efficiency, increased payload capacity, and extended range capabilities.

The aerospace industry's push toward lighter materials has made aircraft carbon fiber an invaluable resource in meeting increasingly stringent environmental regulations and operational cost targets. Airlines can realize substantial fuel savings over an aircraft's lifetime, while simultaneously reducing their carbon footprint and environmental impact.

Safety Enhancements Through Advanced Materials

Impact Resistance and Crash Safety

Aircraft carbon fiber composites exhibit exceptional energy absorption properties during impact events. These materials can be engineered to progressively deform and dissipate energy in a controlled manner, providing superior crash protection compared to traditional metallic structures. The ability to design specific crush zones and energy absorption patterns has revolutionized aircraft safety systems.

Modern aircraft utilizing carbon fiber components demonstrate enhanced survivability in emergency situations. The material's ability to maintain structural integrity while absorbing impact energy helps protect passengers and critical aircraft systems during emergency landings or unusual flight conditions.

Environmental Durability

Aircraft carbon fiber materials show remarkable resistance to environmental factors that typically affect traditional aerospace materials. These composites resist corrosion, temperature extremes, and UV radiation, maintaining their structural properties throughout the aircraft's service life. This durability reduces the risk of material degradation and ensures consistent safety performance over time.

The resistance to environmental factors also translates into reduced maintenance requirements and longer service intervals, allowing operators to maintain high safety standards while optimizing operational efficiency. Aircraft carbon fiber components typically require less frequent inspection and replacement compared to their metallic counterparts.

Future Developments and Innovations

Advanced Manufacturing Techniques

The aerospace industry continues to develop innovative manufacturing processes for aircraft carbon fiber components. Automated fiber placement systems, improved resin technologies, and advanced curing methods are enabling the production of increasingly complex and efficient structures. These manufacturing advances ensure higher quality, consistency, and reliability in critical aircraft components.

Research into novel carbon fiber formulations and hybrid materials promises even greater improvements in performance and safety. The integration of nanotechnology and smart materials with aircraft carbon fiber opens new possibilities for real-time structural monitoring and adaptive performance characteristics.

Sustainability and Recycling

As environmental concerns become increasingly important, the aviation industry is developing new methods for recycling and repurposing aircraft carbon fiber materials. Advanced recycling technologies are being implemented to recover and reprocess carbon fiber components, reducing waste and environmental impact while maintaining the material's high-performance characteristics.

The development of sustainable manufacturing processes and recycling solutions ensures that aircraft carbon fiber will continue to play a crucial role in aviation safety while meeting future environmental requirements and regulations.

Frequently Asked Questions

How does aircraft carbon fiber compare to traditional aluminum in terms of safety?

Aircraft carbon fiber offers superior strength-to-weight ratios, better fatigue resistance, and improved impact absorption compared to aluminum. These properties make carbon fiber aircraft components inherently safer, while also providing benefits in terms of fuel efficiency and maintenance requirements.

What is the expected lifespan of carbon fiber aircraft components?

Carbon fiber components typically have a longer service life than traditional materials, often lasting the entire operational lifetime of the aircraft when properly maintained. The material's resistance to fatigue, corrosion, and environmental factors contributes to its extended durability.

How does weather affect aircraft carbon fiber structures?

Aircraft carbon fiber composites are engineered to withstand extreme weather conditions, including temperature variations, humidity, and UV exposure. These materials maintain their structural integrity across a wide range of environmental conditions, providing consistent performance and safety throughout their service life.