The automotive industry continues to face mounting pressure to improve fuel efficiency while maintaining rigorous safety standards. One material that has emerged as a game-changer in this pursuit is automotive carbon fiber, which offers an exceptional strength-to-weight ratio that enables manufacturers to reduce vehicle weight without sacrificing structural integrity. This revolutionary material has transformed how engineers approach vehicle design, allowing them to create lighter, more efficient vehicles that meet increasingly stringent emissions regulations while delivering superior performance and safety characteristics.

Modern vehicles require materials that can withstand extreme forces while contributing to overall efficiency gains. Traditional steel and aluminum components, while proven and reliable, often add unnecessary weight that directly impacts fuel consumption and emissions output. The integration of carbon fiber composites into automotive applications represents a paradigm shift toward advanced materials engineering that prioritizes both performance and environmental responsibility. Understanding the properties and applications of this material is crucial for automotive professionals seeking to optimize their designs for the next generation of vehicles.

Understanding Carbon Fiber Properties in Automotive Applications

Mechanical Characteristics and Performance Benefits

The mechanical properties of automotive carbon fiber make it an ideal candidate for weight reduction initiatives without compromising structural performance. Carbon fiber exhibits tensile strength values that can exceed 3,500 MPa, which is significantly higher than conventional automotive steels that typically range between 400-1,500 MPa. This exceptional strength allows engineers to design components with thinner cross-sections while maintaining equivalent or superior load-bearing capabilities. The modulus of elasticity for carbon fiber composites ranges from 150-500 GPa, providing excellent stiffness characteristics that resist deformation under operational loads.

The fatigue resistance of carbon fiber composites surpasses that of metallic materials in many applications, making it particularly suitable for automotive components subjected to cyclic loading. Unlike metals that can develop stress concentrations and eventual crack propagation, properly designed carbon fiber structures distribute loads more evenly across the material matrix. This characteristic extends component life and reduces maintenance requirements, contributing to overall vehicle reliability. Additionally, the anisotropic nature of carbon fiber allows engineers to orient fibers in specific directions to optimize strength and stiffness properties for particular loading conditions.

Weight Reduction Potential and Density Advantages

The density of automotive carbon fiber composites typically ranges from 1.5-1.6 g/cm³, compared to steel's 7.8 g/cm³ and aluminum's 2.7 g/cm³. This fundamental density advantage translates directly into significant weight savings when carbon fiber components replace traditional materials. In practical automotive applications, weight reductions of 50-70% are commonly achieved when transitioning from steel to carbon fiber components, while aluminum-to-carbon fiber transitions still yield 40-50% weight savings. These reductions have cascading effects throughout the vehicle design, as lighter components reduce the load on suspension systems, brakes, and powertrains.

The weight distribution benefits of carbon fiber extend beyond simple mass reduction. Strategic placement of carbon fiber components allows engineers to optimize the vehicle's center of gravity, improving handling characteristics and stability. This is particularly valuable in performance applications where weight distribution directly affects cornering ability, braking performance, and acceleration dynamics. The ability to fine-tune weight distribution through selective use of carbon fiber components provides designers with unprecedented control over vehicle dynamics and performance characteristics.

Safety Considerations and Structural Integrity

Impact Resistance and Crashworthiness

Safety remains paramount in automotive design, and automotive carbon fiber components must demonstrate exceptional crashworthiness to gain acceptance in production vehicles. Modern carbon fiber composites exhibit excellent energy absorption characteristics during impact events, often outperforming traditional materials in specific crash scenarios. The fiber architecture and resin matrix can be engineered to provide controlled failure modes that absorb impact energy through progressive crushing and delamination, protecting occupants during collisions.

Advanced carbon fiber structures incorporate features such as crush zones and energy-absorbing elements that manage impact forces effectively. The predictable failure characteristics of well-designed carbon fiber components allow engineers to create structures that maintain passenger compartment integrity while dissipating crash energy through predetermined failure sequences. This level of control over failure modes is difficult to achieve with conventional materials and represents a significant advancement in automotive safety engineering.

Durability and Long-term Performance

The durability of automotive carbon fiber under real-world operating conditions has been extensively validated through both laboratory testing and field experience. Carbon fiber composites demonstrate excellent resistance to corrosion, a significant advantage over steel components that require protective coatings and treatments. This corrosion resistance ensures consistent structural performance throughout the vehicle's operational life, maintaining safety margins that might degrade in metallic components due to environmental exposure.

Temperature stability represents another critical safety consideration, and modern carbon fiber systems maintain their mechanical properties across the full range of automotive operating temperatures. From extreme cold conditions that might cause material embrittlement to high-temperature environments near exhaust systems and engine components, properly formulated carbon fiber composites retain their structural integrity. This temperature stability ensures that safety-critical components perform consistently regardless of operating conditions or geographic location.

Manufacturing Processes and Quality Control

Advanced Composite Manufacturing Techniques

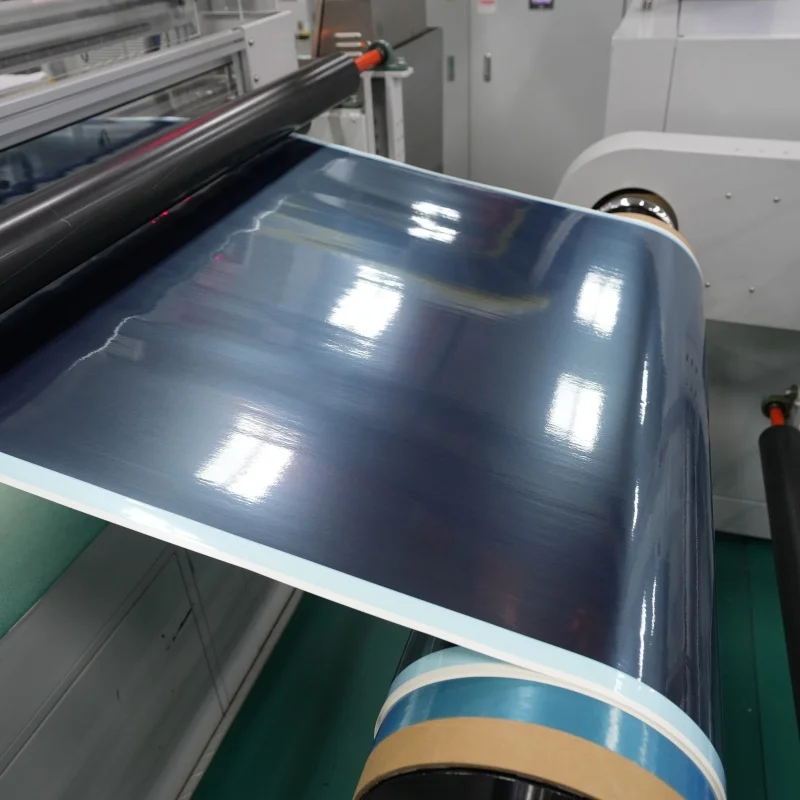

The production of automotive carbon fiber components requires sophisticated manufacturing processes that ensure consistent quality and performance. Prepreg manufacturing, where carbon fibers are pre-impregnated with resin systems, provides precise control over fiber-to-resin ratios and enables the creation of complex geometries with consistent properties. Autoclave curing processes apply controlled temperature and pressure profiles that optimize the cross-linking of resin matrices while eliminating voids and ensuring complete fiber wet-out. These controlled manufacturing environments are essential for achieving the quality levels required for safety-critical automotive applications.

Resin transfer molding (RTM) and vacuum-assisted resin transfer molding (VARTM) processes have gained prominence in automotive applications due to their ability to produce high-quality components with excellent surface finishes and dimensional accuracy. These closed-mold processes minimize volatile emissions while providing precise control over fiber orientation and resin distribution. The repeatability of these manufacturing processes ensures that each component meets stringent automotive quality standards and maintains consistent performance characteristics across production runs.

Quality Assurance and Testing Protocols

Rigorous quality control measures are essential for automotive carbon fiber components, given their safety-critical nature. Non-destructive testing methods such as ultrasonic inspection, thermography, and computed tomography enable manufacturers to detect internal defects, delaminations, or voids that could compromise component performance. These inspection techniques provide comprehensive evaluation of component integrity without damaging the parts, ensuring that only components meeting specification requirements enter the automotive supply chain.

Statistical process control systems monitor key manufacturing parameters throughout production, identifying trends or variations that might affect component quality. Real-time monitoring of temperature, pressure, and cure cycles ensures consistent processing conditions, while automated fiber placement systems provide precise control over fiber orientation and layup sequences. These quality systems enable manufacturers to maintain the tight tolerances and consistent properties required for automotive applications while documenting traceability for regulatory compliance.

Applications in Modern Vehicle Design

Body Panel Integration and Aerodynamic Enhancement

The integration of automotive carbon fiber into body panels represents one of the most visible applications of this advanced material technology. Carbon fiber hoods, doors, and fender panels can reduce vehicle weight by 40-60% compared to steel equivalents while providing superior dent resistance and dimensional stability. The design flexibility of carbon fiber allows manufacturers to create complex aerodynamic shapes that would be difficult or impossible to achieve with traditional stamping processes. These aerodynamic enhancements contribute to improved fuel efficiency and reduced wind noise, providing both performance and comfort benefits.

The surface finish quality achievable with carbon fiber body panels has improved dramatically with advances in manufacturing technology and resin systems. Class-A surface finishes comparable to traditional automotive paint systems can be achieved directly from the mold, reducing finishing operations and associated costs. The dimensional stability of carbon fiber panels under temperature variations provides consistent gap and flush relationships, maintaining the premium appearance expected in modern vehicles. Additionally, the inherent vibration damping characteristics of carbon fiber composites contribute to reduced panel resonance and improved acoustic performance.

Structural Components and Chassis Applications

Structural applications of automotive carbon fiber extend beyond cosmetic panels to include safety-critical chassis components and space frame elements. Carbon fiber roof pillars, door frames, and floor pan sections provide excellent strength-to-weight ratios while contributing to overall vehicle stiffness and crashworthiness. The ability to tailor fiber orientations allows engineers to optimize structural components for specific loading conditions, creating structures that efficiently manage the various forces encountered during normal operation and crash events.

Advanced chassis designs incorporating carbon fiber elements can achieve weight reductions of 30-50% compared to traditional steel constructions while maintaining or improving torsional stiffness. This combination of reduced weight and increased stiffness directly translates to improved vehicle dynamics, more precise handling characteristics, and enhanced occupant comfort through reduced noise, vibration, and harshness (NVH) levels. The integration of carbon fiber structural elements also enables more efficient packaging of vehicle systems, as the material's strength allows for thinner sections that free up valuable interior space.

Economic Considerations and Market Adoption

Cost Analysis and Value Proposition

The economic viability of automotive carbon fiber implementation requires careful consideration of both direct material costs and indirect benefits such as fuel savings and performance improvements. While carbon fiber materials command premium pricing compared to traditional materials, the total cost of ownership often favors carbon fiber when considering factors such as reduced fuel consumption, extended component life, and potential insurance benefits due to improved safety characteristics. The weight reduction achieved through carbon fiber implementation directly translates to improved fuel economy, with every 10% reduction in vehicle weight typically yielding 6-8% improvement in fuel efficiency.

Manufacturing cost reductions have made carbon fiber more accessible to mainstream automotive applications through advances in automated production processes and supply chain optimization. High-volume manufacturing techniques such as compression molding and automated fiber placement have reduced labor costs while improving consistency and quality. The development of lower-cost carbon fiber precursors and recycling technologies continues to drive down material costs, making carbon fiber implementation economically viable for an expanding range of vehicle segments beyond luxury and performance applications.

Supply Chain Development and Scalability

The automotive industry's adoption of carbon fiber has driven significant investments in supply chain infrastructure and manufacturing capacity. Major carbon fiber producers have established regional manufacturing facilities to serve automotive customers, reducing transportation costs and lead times while providing technical support for application development. The establishment of local supply chains has also improved supply security and reduced exposure to global supply disruptions that can affect automotive production schedules.

Scalability remains a key consideration for widespread automotive carbon fiber adoption, as the automotive industry requires massive production volumes with consistent quality and pricing. Continuous fiber production technologies and large-scale precursor manufacturing have increased available capacity while reducing unit costs through economies of scale. The development of recycling technologies for carbon fiber composites addresses sustainability concerns while creating additional supply sources, further supporting the economic viability of automotive carbon fiber applications.

Future Trends and Technological Developments

Advanced Fiber Technologies and Hybrid Materials

The future of automotive carbon fiber involves the development of advanced fiber technologies that further enhance performance while reducing costs. High-strength, intermediate-modulus carbon fibers provide improved mechanical properties at competitive pricing, making them attractive for high-volume automotive applications. Hybrid material systems combining carbon fiber with other advanced materials such as natural fibers or recycled content offer opportunities to optimize performance and sustainability while managing costs for specific applications.

Nanotechnology integration promises to enhance the properties of automotive carbon fiber through the incorporation of carbon nanotubes, graphene, and other nanoscale reinforcements. These advanced materials can improve electrical conductivity, thermal management, and mechanical properties while enabling new functionalities such as integrated sensors and smart material behaviors. The development of multi-functional carbon fiber systems that combine structural performance with electrical, thermal, or sensing capabilities represents a significant opportunity for next-generation automotive applications.

Manufacturing Innovation and Automation

Advanced manufacturing technologies continue to revolutionize automotive carbon fiber production through increased automation and process optimization. Robotic fiber placement systems provide unprecedented precision in component fabrication while reducing labor costs and improving consistency. Machine learning algorithms optimize cure cycles and process parameters in real-time, maximizing quality while minimizing cycle times and energy consumption. These technological advances are essential for achieving the cost and volume targets required for mainstream automotive adoption.

Digital manufacturing technologies including simulation software and virtual prototyping enable rapid development and optimization of carbon fiber components without extensive physical testing. These tools reduce development time and costs while improving component performance through better understanding of material behavior and optimization of design parameters. The integration of digital technologies throughout the manufacturing process enables predictive maintenance, quality monitoring, and continuous improvement initiatives that further enhance the economic viability of automotive carbon fiber applications.

FAQ

What are the primary safety benefits of using automotive carbon fiber compared to traditional materials?

Automotive carbon fiber offers superior impact energy absorption, predictable failure modes during crashes, excellent fatigue resistance, and corrosion immunity that maintains structural integrity over time. The material's high strength-to-weight ratio enables thinner, lighter components that still meet or exceed safety requirements while contributing to overall vehicle stability through optimized weight distribution.

How much weight reduction can be achieved by replacing steel components with carbon fiber?

Weight reductions of 50-70% are commonly achieved when replacing steel components with carbon fiber alternatives, while aluminum-to-carbon fiber transitions typically yield 40-50% weight savings. The actual reduction depends on component design, manufacturing process, and performance requirements, with some applications achieving even greater savings through design optimization.

What manufacturing processes ensure consistent quality in automotive carbon fiber components?

Key manufacturing processes include prepreg layup with autoclave curing, resin transfer molding (RTM), and vacuum-assisted resin transfer molding (VARTM). Quality assurance involves non-destructive testing methods such as ultrasonic inspection and thermography, combined with statistical process control systems that monitor temperature, pressure, and cure parameters throughout production.

How does the cost of automotive carbon fiber compare to traditional materials over the vehicle's lifetime?

While carbon fiber has higher initial material costs, the total cost of ownership often favors carbon fiber due to fuel savings from weight reduction, extended component life, reduced maintenance requirements, and potential insurance benefits from improved safety. Every 10% reduction in vehicle weight typically provides 6-8% improvement in fuel efficiency, creating long-term economic benefits that offset higher initial costs.

Table of Contents

- Understanding Carbon Fiber Properties in Automotive Applications

- Safety Considerations and Structural Integrity

- Manufacturing Processes and Quality Control

- Applications in Modern Vehicle Design

- Economic Considerations and Market Adoption

- Future Trends and Technological Developments

-

FAQ

- What are the primary safety benefits of using automotive carbon fiber compared to traditional materials?

- How much weight reduction can be achieved by replacing steel components with carbon fiber?

- What manufacturing processes ensure consistent quality in automotive carbon fiber components?

- How does the cost of automotive carbon fiber compare to traditional materials over the vehicle's lifetime?